Page 19 - PowerPoint Sunusu

P. 19

klebstoffe montage technik !

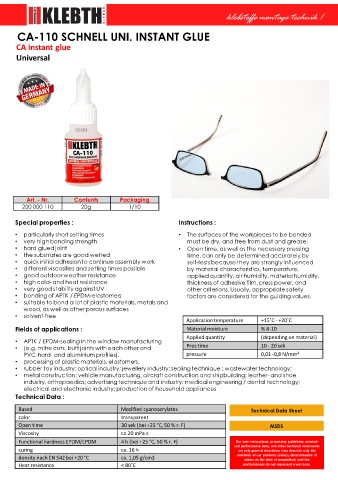

CA-110 SCHNELL UNI. INSTANT GLUE

CA Instant glue

Universal

Art. - Nr. Contents Packaging

200 000 110 20g 1/10

Special properties : Instructions :

• particularly short setting times • The surfaces of the workpieces to be bonded

• very high bonding strength must be dry, and free from dust and grease.

• hard glued joint • Open time, as well as the necessary pressing

• the substrates are good wetted time, can only be determined accurately by

• quick initial adhesion to continue assembly work self-tests because they are strongly influenced

• different viscosities and setting times possible by material characteristics, temperature,

• good outdoor weather resistance applied quantity, air humidity, material humidity,

• high cold- and heat resistance thickness of adhesive film, press power, and

• very good stability against UV other criterions. Usually, appropriate safety

• bonding of APTK / EPDM-elastomers factors are considered for the guiding values.

• suitable to bond a lot of plastic materials, metals and

wood, as well as other porous surfaces

• solvent-free

Applicationtemperature +15˚C - +20˚C

Fields of applications : Material moisture % 8-10

Applied quantity (depending on material)

• APTK / EPDM-sealing in the window manufacturing

• (e.g. mitre cuts, butt joints with each other and Pres time 10 - 20 sek

PVC-hard- and aluminium profiles). pressure 0,01 -0,8 N/mm²

• processing of plastic materials, elastomers,

• rubber toy industry; optical industry; jewellery industry; sealing technique ; wastewater technology;

• metal construction; vehicle manufacturing, aircraft construction and shipbuilding; leather- and shoe

industry, orthopaedics; advertising technique and industry; medical engineering / dental technology;

electrical and electronic industry; production of household appliances

Technical Data :

Based Modified cyanoacrylates Technical Data Sheet

color transparent

Open time 30 sek (bei +25 °C, 50 % r. F) MSDS

Viscosity ca.20 mPa.s

Functional hardness EPDM/EPDM 4 h (bei +25 °C, 50 % r. F) Our user instructions, processing guidelines, product-

and performance data, and other technical statements

curing ca. 16 h are only general directives; they describe only the

condition of our products (values, determination of

density nach EN 542 bei +20 °C ca. 1,05 g/cm3 values on the date of completion) and the

Heat resistance < 80˚C performances do not represent a warranty.