Page 6 - GVA Northwest

P. 6

Page No. 6

Proposal No. Q09526

Date: March 12, 2014

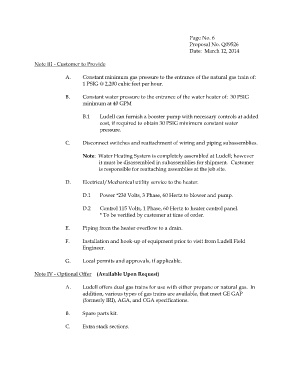

Note III - Customer to Provide

A. Constant minimum gas pressure to the entrance of the natural gas train of:

1 PSIG @ 2,200 cubic feet per hour.

B. Constant water pressure to the entrance of the water heater of: 30 PSIG

minimum at 40 GPM

B.1 Ludell can furnish a booster pump with necessary controls at added

cost, if required to obtain 30 PSIG minimum constant water

pressure.

C. Disconnect switches and reattachment of wiring and piping subassemblies.

Note: Water Heating System is completely assembled at Ludell; however

it must be disassembled in subassemblies for shipment. Customer

is responsible for reattaching assemblies at the job site.

D. Electrical/Mechanical utility service to the heater.

D.1 Power *230 Volts, 3 Phase, 60 Hertz to blower and pump.

D.2 Control 115 Volts, 1 Phase, 60 Hertz to heater control panel.

* To be verified by customer at time of order.

E. Piping from the heater overflow to a drain.

F. Installation and hook-up of equipment prior to visit from Ludell Field

Engineer.

G. Local permits and approvals, if applicable.

Note IV - Optional Offer (Available Upon Request)

A. Ludell offers dual gas trains for use with either propane or natural gas. In

addition, various types of gas trains are available, that meet GE GAP

(formerly IRI), AGA, and CGA specifications.

B. Spare parts kit.

C. Extra stack sections.