Page 146 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 146

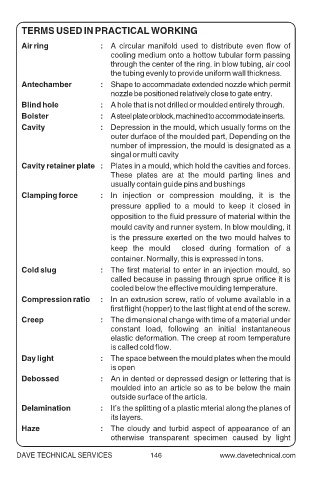

TERMS USED IN PRACTICAL WORKING

Air ring : A circular manifold used to distribute even flow of

cooling medium onto a hottow tubular form passing

through the center of the ring. in blow tubing, air cool

the tubing evenly to provide uniform wall thickness.

Antechamber : Shape to accommadate extended nozzle which permit

nozzle be positioned relatively close to gate entry.

Blind hole : A hole that is not drilled or moulded entirely through.

Bolster : A steel plate or block, machined to accommodate inserts.

Cavity : Depression in the mould, which usually forms on the

outer durface of the moulded part, Depending on the

number of impression, the mould is designated as a

singal or multi cavity

Cavity retainer plate : Plates in a mould, which hold the cavities and forces.

These plates are at the mould parting lines and

usually contain guide pins and bushings

Clamping force : In injection or compression moulding, it is the

pressure applied to a mould to keep it closed in

opposition to the fluid pressure of material within the

mould cavity and runner system. In blow moulding, it

is the pressure exerted on the two mould halves to

keep the mould closed during formation of a

container. Normally, this is expressed in tons.

Cold slug : The first material to enter in an injection mould, so

called because in passing through sprue orifice it is

cooled below the effective moulding temperature.

Compression ratio : In an extrusion screw, ratio of volume available in a

first flight (hopper) to the last flight at end of the screw.

Creep : The dimensional change with time of a material under

constant load, following an initial instantaneous

elastic deformation. The creep at room temperature

is called cold flow.

Day light : The space between the mould plates when the mould

is open

Debossed : An in dented or depressed design or lettering that is

moulded into an article so as to be below the main

outside surface of the articla.

Delamination : It’s the splitting of a plastic mterial along the planes of

its layers.

Haze : The cloudy and turbid aspect of appearance of an

otherwise transparent specimen caused by light

DAVE TECHNICAL SERVICES 146