Page 147 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 147

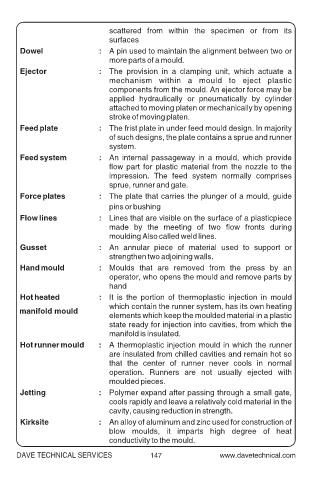

scattered from within the specimen or from its

surfaces

Dowel : A pin used to maintain the alignment between two or

more parts of a mould.

Ejector : The provision in a clamping unit, which actuate a

mechanism within a mould to eject plastic

components from the mould. An ejector force may be

applied hydraulically or pneumatically by cylinder

attached to moving platen or mechanically by opening

stroke of moving platen.

Feed plate : The frist plate in under feed mould design. In majority

of such designs, the plate contains a sprue and runner

system.

Feed system : An internal passageway in a mould, which provide

flow part for plastic material from the nozzle to the

impression. The feed system normally comprises

sprue, runner and gate.

Force plates : The plate that carries the plunger of a mould, guide

pins or bushing

Flow lines : Lines that are visible on the surface of a plasticpiece

made by the meeting of two flow fronts during

moulding Also called weld lines.

Gusset : An annular piece of material used to support or

strengthen two adjoining walls.

Hand mould : Moulds that are removed from the press by an

operator, who opens the mould and remove parts by

hand

Hot heated : It is the portion of thermoplastic injection in mould

which contain the runner system, has its own heating

manifold mould

elements which keep the moulded material in a plastic

state ready for injection into cavities, from which the

manifold is insulated.

Hot runner mould : A thermoplastic injection mould in which the runner

are insulated from chilled cavities and remain hot so

that the center of runner never cools in normal

operation. Runners are not usually ejected with

moulded pieces.

Jetting : Polymer expand after passing through a small gate,

cools rapidly and leave a relatively cold material in the

cavity, causing reduction in strength.

Kirksite : An alloy of aluminum and zinc used for construction of

blow moulds, it imparts high degree of heat

conductivity to the mould.

DAVE TECHNICAL SERVICES 147