Page 148 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 148

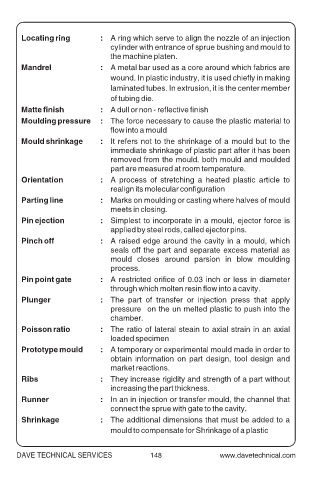

Locating ring : A ring which serve to align the nozzle of an injection

cylinder with entrance of sprue bushing and mould to

the machine platen.

Mandrel : A metal bar used as a core around which fabrics are

wound. In plastic industry, it is used chiefly in making

laminated tubes. In extrusion, it is the center member

of tubing die.

Matte finish : A dull or non - reflective finish

Moulding pressure : The force necessary to cause the plastic material to

flow into a mould

Mould shrinkage : It refers not to the shrinkage of a mould but to the

immediate shrinkage of plastic part after it has been

removed from the mould. both mould and moulded

part are measured at room temperature.

Orientation : A process of stretching a heated plastic article to

realign its molecular configuration

Parting line : Marks on moulding or casting where halves of mould

meets in closing.

Pin ejection : Simplest to incorporate in a mould, ejector force is

applied by steel rods, called ejector pins.

Pinch off : A raised edge around the cavity in a mould, which

seals off the part and separate excess material as

mould closes around parsion in blow moulding

process.

Pin point gate : A restricted orifice of 0.03 inch or less in diameter

through which molten resin flow into a cavity.

Plunger : The part of transfer or injection press that apply

pressure on the un melted plastic to push into the

chamber.

Poisson ratio : The ratio of lateral steain to axial strain in an axial

loaded specimen

Prototype mould : A temporary or experimental mould made in order to

obtain information on part design, tool design and

market reactions.

Ribs : They increase rigidity and strength of a part without

increasing the part thickness.

Runner : In an in injection or transfer mould, the channel that

connect the sprue with gate to the cavity.

Shrinkage : The additional dimensions that must be added to a

mould to compensate for Shrinkage of a plastic

DAVE TECHNICAL SERVICES 148