Page 201 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 201

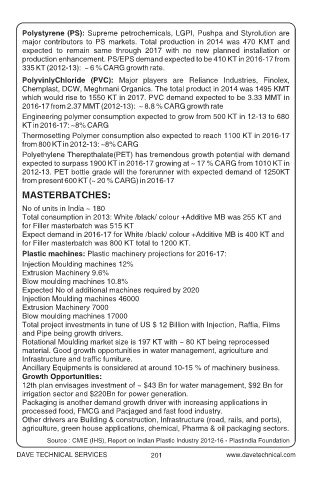

Polystyrene (PS): Supreme petrochemicals, LGPI, Pushpa and Styrolution are

major contributors to PS markets. Total production in 2014 was 470 KMT and

expected to remain same through 2017 with no new planned installation or

production enhancement. PS/EPS demand expected to be 410 KT in 2016-17 from

335 KT (2012-13): ~ 6 % CARG growth rate.

PolyvinlyChloride (PVC): Major players are Reliance Industries, Finolex,

Chemplast, DCW, Meghmani Organics. The total product in 2014 was 1495 KMT

which would rise to 1550 KT in 2017. PVC demand expected to be 3.33 MMT in

2016-17 from 2.37 MMT (2012-13): ~ 8.8 % CARG growth rate

Engineering polymer consumption expected to grow from 500 KT in 12-13 to 680

KT in 2016-17: ~8% CARG

Thermosetting Polymer consumption also expected to reach 1100 KT in 2016-17

from 800 KT in 2012-13: ~8% CARG

Polyethylene Therepthalate(PET) has tremendous growth potential with demand

expected to surpass 1900 KT in 2016-17 growing at ~ 17 % CARG from 1010 KT in

2012-13. PET bottle grade will the forerunner with expected demand of 1250KT

from present 600 KT (~ 20 % CARG) in 2016-17

MASTERBATCHES:

No of units in India ~ 180

Total consumption in 2013: White /black/ colour +Additive MB was 255 KT and

for Filler masterbatch was 515 KT

Expect demand in 2016-17 for White /black/ colour +Additive MB is 400 KT and

for Filler masterbatch was 800 KT total to 1200 KT.

Plastic machines: Plastic machinery projections for 2016-17:

Injection Moulding machines 12%

Extrusion Machinery 9.6%

Blow moulding machines 10.8%

Expected No of additional machines required by 2020

Injection Moulding machines 46000

Extrusion Machinery 7000

Blow moulding machines 17000

Total project investments in tune of US $ 12 Billion with Injection, Raffia, Films

and Pipe being growth drivers.

Rotational Moulding market size is 197 KT with ~ 80 KT being reprocessed

material. Good growth opportunities in water management, agriculture and

Infrastructure and traffic furniture.

Ancillary Equipments is considered at around 10-15 % of machinery business.

Growth Opportunities:

12th plan envisages investment of ~ $43 Bn for water management, $92 Bn for

irrigation sector and $220Bn for power generation.

Packaging is another demand growth driver with increasing applications in

processed food, FMCG and Pacjaged and fast food industry.

Other drivers are Building & construction, Infrastructure (road, rails, and ports),

agriculture, green house applications, chemical, Pharma & oil packaging sectors.

Source : CMIE (IHS), Report on Indian Plastic Industry 2012-16 - Plastindia Foundation

DAVE TECHNICAL SERVICES 201 www.davetechnical.com