Page 40 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 40

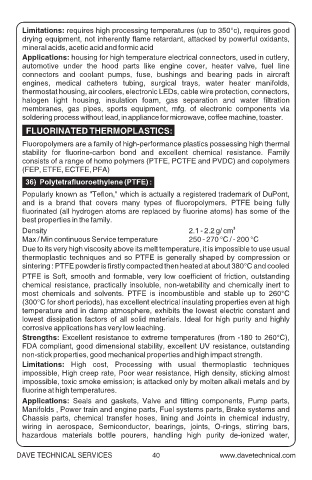

Limitations: requires high processing temperatures (up to 350°c), requires good

drying equipment, not inherently flame retardant, attacked by powerful oxidants,

mineral acids, acetic acid and formic acid

Applications: housing for high temperature electrical connectors, used in cutlery,

automotive under the hood parts like engine cover, heater valve, fuel line

connectors and coolant pumps, fuse, bushings and bearing pads in aircraft

engines, medical catheters tubing, surgical trays, water heater manifolds,

thermostat housing, air coolers, electronic LEDs, cable wire protection, connectors,

halogen light housing, insulation foam, gas separation and water filtration

membranes, gas pipes, sports equipment, mfg. of electronic components via

soldering process without lead, in appliance for microwave, coffee machine, toaster.

FLUORINATED THERMOPLASTICS:

Fluoropolymers are a family of high-performance plastics possessing high thermal

stability for fluorine-carbon bond and excellent chemical resistance. Family

consists of a range of homo polymers (PTFE, PCTFE and PVDC) and copolymers

(FEP, ETFE, ECTFE, PFA)

36) Polytetrafluoroethylene (PTFE) :

Popularly known as "Teflon," which is actually a registered trademark of DuPont,

and is a brand that covers many types of fluoropolymers. PTFE being fully

fluorinated (all hydrogen atoms are replaced by fluorine atoms) has some of the

best properties in the family.

Density 2.1 - 2.2 g/ cm 3

Max / Min continuous Service temperature 250 - 270 °C / - 200 °C

Due to its very high viscosity above its melt temperature, it is impossible to use usual

thermoplastic techniques and so PTFE is generally shaped by compression or

sintering : PTFE powder is firstly compacted then heated at about 380°C and cooled

PTFE is Soft, smooth and formable, very low coefficient of friction, outstanding

chemical resistance, practically insoluble, non-wetability and chemically inert to

most chemicals and solvents. PTFE is incombustible and stable up to 260°C

(300°C for short periods), has excellent electrical insulating properties even at high

temperature and in damp atmosphere, exhibits the lowest electric constant and

lowest dissipation factors of all solid materials. Ideal for high purity and highly

corrosive applications has very low leaching.

Strengths: Excellent resistance to extreme temperatures (from -180 to 260°C),

FDA compliant, good dimensional stability, excellent UV resistance, outstanding

non-stick properties, good mechanical properties and high impact strength.

Limitations: High cost, Processing with usual thermoplastic techniques

impossible, High creep rate, Poor wear resistance, High density, sticking almost

impossible, toxic smoke emission; is attacked only by molten alkali metals and by

fluorine at high temperatures.

Applications: Seals and gaskets, Valve and fitting components, Pump parts,

Manifolds , Power train and engine parts, Fuel systems parts, Brake systems and

Chassis parts, chemical transfer hoses, lining and Joints in chemical industry,

wiring in aerospace, Semiconductor, bearings, joints, O-rings, stirring bars,

hazardous materials bottle pourers, handling high purity de-ionized water,

DAVE TECHNICAL SERVICES 40