Page 41 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 41

evaporating dishes, Non Stick coating on frying pans, utensils , Cable jacketing,

Insulation tapes, Terminal sockets, bio-medical applications

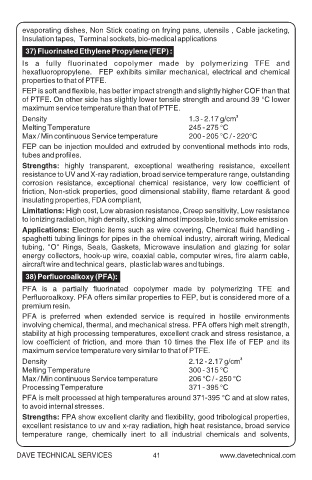

37) Fluorinated Ethylene Propylene (FEP) :

Is a fully fluorinated copolymer made by polymerizing TFE and

hexafluoropropylene. FEP exhibits similar mechanical, electrical and chemical

properties to that of PTFE.

FEP is soft and flexible, has better impact strength and slightly higher COF than that

of PTFE. On other side has slightly lower tensile strength and around 39 °C lower

maximum service temperature than that of PTFE.

Density 1.3 - 2.17 g/cm 3

Melting Temperature 245 - 275 °C

Max / Min continuous Service temperature 200 - 205 °C / - 220°C

FEP can be injection moulded and extruded by conventional methods into rods,

tubes and profiles.

Strengths: highly transparent, exceptional weathering resistance, excellent

resistance to UV and X-ray radiation, broad service temperature range, outstanding

corrosion resistance, exceptional chemical resistance, very low coefficient of

friction, Non-stick properties, good dimensional stability, flame retardant & good

insulating properties, FDA compliant,

Limitations: High cost, Low abrasion resistance, Creep sensitivity, Low resistance

to ionizing radiation, high density, sticking almost impossible, toxic smoke emission

Applications: Electronic items such as wire covering, Chemical fluid handling -

spaghetti tubing linings for pipes in the chemical industry, aircraft wiring, Medical

tubing, "O" Rings, Seals, Gaskets, Microwave insulation and glazing for solar

energy collectors, hook-up wire, coaxial cable, computer wires, fire alarm cable,

aircraft wire and technical gears, plastic lab wares and tubings.

38) Perfluoroalkoxy (PFA):

PFA is a partially fluorinated copolymer made by polymerizing TFE and

Perfluoroalkoxy. PFA offers similar properties to FEP, but is considered more of a

premium resin.

PFA is preferred when extended service is required in hostile environments

involving chemical, thermal, and mechanical stress. PFA offers high melt strength,

stability at high processing temperatures, excellent crack and stress resistance, a

low coefficient of friction, and more than 10 times the Flex life of FEP and its

maximum service temperature very similar to that of PTFE.

Density 2.12 - 2.17 g/cm 3

Melting Temperature 300 - 315 °C

Max / Min continuous Service temperature 206 °C / - 250 °C

Processing Temperature 371 - 395 °C

PFA is melt processed at high temperatures around 371-395 °C and at slow rates,

to avoid internal stresses.

Strengths: FPA show excellent clarity and flexibility, good tribological properties,

excellent resistance to uv and x-ray radiation, high heat resistance, broad service

temperature range, chemically inert to all industrial chemicals and solvents,

DAVE TECHNICAL SERVICES 41