Page 43 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 43

Glass transition temperature 85 °C

Processing Temperature 252 - 282 °C

ECTFE is available in the form of translucent pellets, as a fine powder that can be

extruded or moulded, can be processed into films.

ECTFE is virtually unaffected by most corrosive chemicals, high impact strength

and has a wide continuous usage temperature range between –76°C and +150°C.

ECTFE has mechanical properties approaching those of fully fluorinated polymers

(PTFE, PCTFE, PVDC) with a lower maximum service temperature and the lowest

density. As with ETFE, ECTFE has excellent cut through, abrasion resistance and

impact strength.

Strengths: Excellent resistance to abrasion, outstanding chemical resistance,

processed with conventional thermoplastic techniques, excellent electrical

properties, high impact strength, especially at low temperatures excellent

resistance to radiation, good wear resistance, high purity, Intrinsic Flame retardant.

Limitations: Very high cost, Max. use temperature lower than other fluoropolymers

(150°C), Attacked by esters and aromatic hydrocarbons, High density

Applications: Cable jacketing, Protective linings and coatings, Expansion joints,

Pumps, Valves, Fittings, Gaskets, films retains integrity when exposed to harsh

chemicals and strong polar solvents making it suitable for water purification

systems, aggressive cleaning agents simply increase ECTFE membrane flux and

overall operating efficiency. ECTFE film vapour barrier properties make it

particularly suitable for use in pharmaceutical packaging applications.

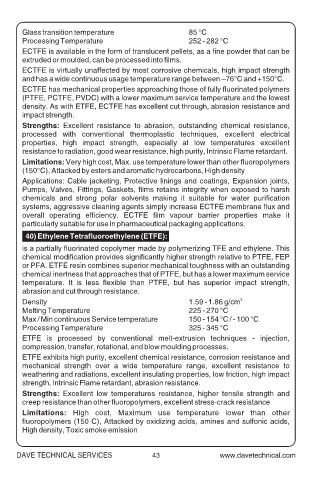

40) Ethylene Tetrafluoroethylene (ETFE):

is a partially fluorinated copolymer made by polymerizing TFE and ethylene. This

chemical modification provides significantly higher strength relative to PTFE, FEP

or PFA. ETFE resin combines superior mechanical toughness with an outstanding

chemical inertness that approaches that of PTFE, but has a lower maximum service

temperature. It is less flexible than PTFE, but has superior impact strength,

abrasion and cut through resistance.

Density 1.59 - 1.86 g/cm 3

Melting Temperature 225 - 270 °C

Max / Min continuous Service temperature 150 - 154 °C / - 100 °C

Processing Temperature 325 - 345 °C

ETFE is processed by conventional melt-extrusion techniques - injection,

compression, transfer, rotational, and blow moulding processes.

ETFE exhibits high purity, excellent chemical resistance, corrosion resistance and

mechanical strength over a wide temperature range, excellent resistance to

weathering and radiations, excellent insulating properties, low friction, high impact

strength, Intrinsic Flame retardant, abrasion resistance.

Strengths: Excellent low temperatures resistance, higher tensile strength and

creep resistance than other fluoropolymers, excellent stress-crack resistance

Limitations: High cost, Maximum use temperature lower than other

fluoropolymers (150 C), Attacked by oxidizing acids, amines and sulfonic acids,

High density, Toxic smoke emission

DAVE TECHNICAL SERVICES 43