Page 44 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 44

Applications: chemical process tank construction and linings, pump impellers or

moving parts of equipment that are operating in chemically aggressive

environments, Cryogenic applications, super-cold refrigeration components,

Valves linings, seats, seals, Electrical & electronic components, insulators, cable

clamps, encapsulated parts, sockets, Medical centrifuge tubes, Blood analyzer

valves, oxygen respirator components, Gaskets pressure diaphragm, liquid gauge

seals, fluid handling, Films for food packaging, pharmaceutical packaging, optical

recording, electroluminescent display panels.

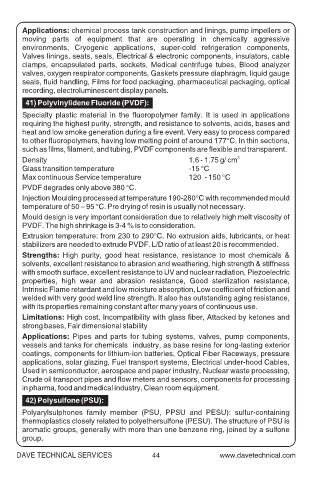

41) Polyvinylidene Fluoride (PVDF):

Specialty plastic material in the fluoropolymer family. It is used in applications

requiring the highest purity, strength, and resistance to solvents, acids, bases and

heat and low smoke generation during a fire event. Very easy to process compared

to other fluoropolymers, having low melting point of around 177°C. In thin sections,

such as films, filament, and tubing, PVDF components are flexible and transparent.

Density 1.6 - 1.75 g/ cm 3

Glass transition temperature -15 °C

Max continuous Service temperature 120 - 150 °C

PVDF degrades only above 380 °C.

Injection Moulding processed at temperature 190-280°C with recommended mould

temperature of 50 – 95 °C. Pre drying of resin is usually not necessary.

Mould design is very important consideration due to relatively high melt viscosity of

PVDF. The high shrinkage is 3-4 % is to consideration.

Extrusion temperature: from 230 to 290°C. No extrusion aids, lubricants, or heat

stabilizers are needed to extrude PVDF. L/D ratio of at least 20 is recommended.

Strengths: High purity, good heat resistance, resistance to most chemicals &

solvents, excellent resistance to abrasion and weathering, high strength & stiffness

with smooth surface, excellent resistance to UV and nuclear radiation, Piezoelectric

properties, high wear and abrasion resistance, Good sterilization resistance,

Intrinsic Flame retardant and low moisture absorption, Low coefficient of friction and

welded with very good weld line strength. It also has outstanding aging resistance,

with its properties remaining constant after many years of continuous use.

Limitations: High cost, Incompatibility with glass fiber, Attacked by ketones and

strong bases, Fair dimensional stability

Applications: Pipes and parts for tubing systems, valves, pump components,

vessels and tanks for chemicals industry, as base resins for long-lasting exterior

coatings, components for lithium-ion batteries, Optical Fiber Raceways, pressure

applications, solar glazing, Fuel transport systems, Electrical under-hood Cables,

Used in semiconductor, aerospace and paper industry, Nuclear waste processing,

Crude oil transport pipes and flow meters and sensors, components for processing

in pharma, food and medical industry, Clean room equipment.

42) Polysulfone (PSU):

Polyarylsulphones family member (PSU, PPSU and PESU): sulfur-containing

thermoplastics closely related to polyethersulfone (PESU). The structure of PSU is

aromatic groups, generally with more than one benzene ring, joined by a sulfone

group.

DAVE TECHNICAL SERVICES 44