Page 46 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 46

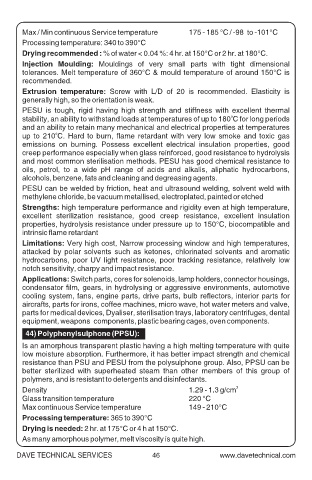

Max / Min continuous Service temperature 175 - 185 °C / -98 to -101°C

Processing temperature: 340 to 390°C

Drying recommended : % of water < 0.04 %: 4 hr. at 150°C or 2 hr. at 180°C.

Injection Moulding: Mouldings of very small parts with tight dimensional

tolerances. Melt temperature of 360°C & mould temperature of around 150°C is

recommended.

Extrusion temperature: Screw with L/D of 20 is recommended. Elasticity is

generally high, so the orientation is weak.

PESU is tough, rigid having high strength and stiffness with excellent thermal

o

stability, an ability to withstand loads at temperatures of up to 180 C for long periods

and an ability to retain many mechanical and electrical properties at temperatures

o

up to 210 C. Hard to burn, flame retardant with very low smoke and toxic gas

emissions on burning. Possess excellent electrical insulation properties, good

creep performance especially when glass reinforced, good resistance to hydrolysis

and most common sterilisation methods. PESU has good chemical resistance to

oils, petrol, to a wide pH range of acids and alkalis, aliphatic hydrocarbons,

alcohols, benzene, fats and cleaning and degreasing agents.

PESU can be welded by friction, heat and ultrasound welding, solvent weld with

methylene chloride, be vacuum metallised, electroplated, painted or etched

Strengths: high temperature performance and rigidity even at high temperature,

excellent sterilization resistance, good creep resistance, excellent insulation

properties, hydrolysis resistance under pressure up to 150°C, biocompatible and

intrinsic flame retardant

Limitations: Very high cost, Narrow processing window and high temperatures,

attacked by polar solvents such as ketones, chlorinated solvents and aromatic

hydrocarbons, poor UV light resistance, poor tracking resistance, relatively low

notch sensitivity, charpy and impact resistance.

Applications: Switch parts, cores for solenoids, lamp holders, connector housings,

condensator film, gears, in hydrolysing or aggressive environments, automotive

cooling system, fans, engine parts, drive parts, bulb reflectors, interior parts for

aircrafts, parts for irons, coffee machines, micro wave, hot water meters and valve,

parts for medical devices, Dyaliser, sterilisation trays, laboratory centrifuges, dental

equipment, weapons components, plastic bearing cages, oven components.

44) Polyphenylsulphone (PPSU):

Is an amorphous transparent plastic having a high melting temperature with quite

low moisture absorption. Furthermore, it has better impact strength and chemical

resistance than PSU and PESU from the polysulphone group. Also, PPSU can be

better sterilized with superheated steam than other members of this group of

polymers, and is resistant to detergents and disinfectants.

Density 1.29 - 1.3 g/cm 3

Glass transition temperature 220 °C

Max continuous Service temperature 149 - 210°C

Processing temperature: 365 to 390°C

Drying is needed: 2 hr. at 175°C or 4 h at 150°C.

As many amorphous polymer, melt viscosity is quite high.

DAVE TECHNICAL SERVICES 46