Page 50 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 50

impact resistance than most advanced engineering plastics. PAI resins are higher

in thermal stability compared to PEI or polyester enamels.

Strengths: Self-lubricating, Thermal stability, Exceptional strength and

Dimensional stability, High elongation, Conformability (non-leaking)

Limitations: Very high temperature processing, Polyamide-imide is reactive,

Molecular weight and so viscosity increases with temperature, Risk of “seizing”

screw & barrel, Regrind STRONGLY discouraged

Applications: Aircraft hardware and fasteners, Mechanical gears, seals,

fasteners, slides, bushing, thrust washers, and structural components,

Transmission and power train components, Coatings, composites, additives, Oil

and gas exploration and recovery equipment, Electric motor components,

Semiconductor fabrication and testing

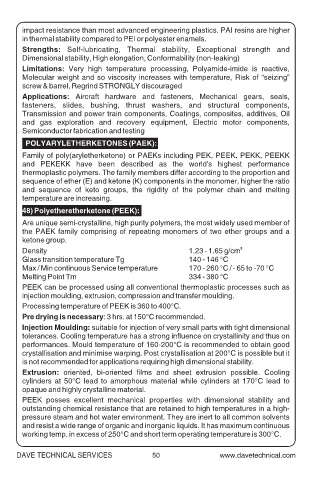

POLYARYLETHERKETONES (PAEK):

Family of poly(aryletherketone) or PAEKs including PEK, PEEK, PEKK, PEEKK

and PEKEKK have been described as the world's highest performance

thermoplastic polymers. The family members differ according to the proportion and

sequence of ether (E) and ketone (K) components in the monomer, higher the ratio

and sequence of keto groups, the rigidity of the polymer chain and melting

temperature are increasing.

48) Polyetheretherketone (PEEK):

Are unique semi-crystalline, high purity polymers, the most widely used member of

the PAEK family comprising of repeating monomers of two ether groups and a

ketone group.

Density 1.23 - 1.65 g/cm 3

Glass transition temperature Tg 140 - 146 °C

Max / Min continuous Service temperature 170 - 260 °C / - 65 to -70 °C

Melting Point Tm 334 - 380 °C

PEEK can be processed using all conventional thermoplastic processes such as

injection moulding, extrusion, compression and transfer moulding.

Processing temperature of PEEK is 360 to 400°C.

Pre drying is necessary: 3 hrs. at 150°C recommended.

Injection Moulding: suitable for injection of very small parts with tight dimensional

tolerances. Cooling temperature has a strong influence on crystallinity and thus on

performances. Mould temperature of 160-200°C is recommended to obtain good

crystallisation and minimise warping. Post crystallisation at 200°C is possible but it

is not recommended for applications requiring high dimensional stability.

Extrusion: oriented, bi-oriented films and sheet extrusion possible. Cooling

cylinders at 50°C lead to amorphous material while cylinders at 170°C lead to

opaque and highly crystalline material.

PEEK posses excellent mechanical properties with dimensional stability and

outstanding chemical resistance that are retained to high temperatures in a high-

pressure steam and hot water environment. They are inert to all common solvents

and resist a wide range of organic and inorganic liquids. It has maximum continuous

working temp. in excess of 250°C and short term operating temperature is 300°C.

DAVE TECHNICAL SERVICES 50