Page 55 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 55

thermosets. It can be easily identified by the metallic sound it makes when struck.

Strengths: Machined and precision moulding to tight tolerances, gluable with

acrylate and epoxy glues, weldable through ultrasonic, outstanding performance as

a corrosion-resistant coating suitable for contact with foods, Intrinsically FR (VO),

remarkable long- term 200°C & short term 260°C temperature resistance, PPS

surface can accept vapour metallisation without the need for intermediate painting,

as is normally the case with filled thermoplastics, dielectric and insulating properties

stable over a wide range of conditions.

Limitations: high melt temperature so difficult to process, Low melt viscosity (not

easy to extrude), high cost, medium to poor impact resistance, limited colourability

(naturally brown), Subject to warpage and brittleness, rarely used unfilled.

Applications: electrical and electronic like connectors, terminal blocks, sockets,

coil formers and relay components, automotive under-the-hood ignition systems

parts, brake circuit valves, engine and carburettor parts, thermostats holders,

sensors, reflectors water pump impellers, parts for aircrafts, pumps and blower

parts, grips for appliances like coffee machines, iron, toaster, copier gears, fax

machine heads, sterilisable laboratory equipment and surgical devices, bearings,

bushings, thrust washers, filter fabric for coal boilers, specialty membranes, others.

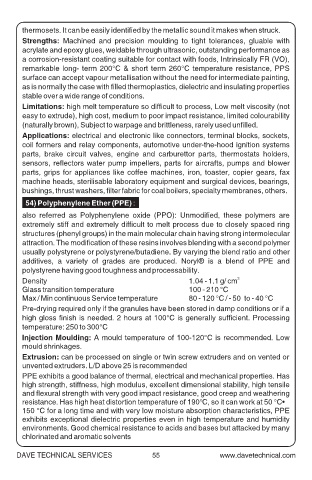

54) Polyphenylene Ether (PPE) :

also referred as Polyphenylene oxide (PPO): Unmodified, these polymers are

extremely stiff and extremely difficult to melt process due to closely spaced ring

structures (phenyl groups) in the main molecular chain having strong intermolecular

attraction. The modification of these resins involves blending with a second polymer

usually polystyrene or polystyrene/butadiene. By varying the blend ratio and other

additives, a variety of grades are produced. Noryl® is a blend of PPE and

polystyrene having good toughness and processability.

Density 1.04 - 1.1 g/ cm 3

Glass transition temperature 100 - 210 °C

Max / Min continuous Service temperature 80 - 120 °C / - 50 to - 40 °C

Pre-drying required only if the granules have been stored in damp conditions or if a

high gloss finish is needed. 2 hours at 100°C is generally sufficient. Processing

temperature: 250 to 300°C

Injection Moulding: A mould temperature of 100-120°C is recommended. Low

mould shrinkages.

Extrusion: can be processed on single or twin screw extruders and on vented or

unvented extruders. L/D above 25 is recommended

PPE exhibits a good balance of thermal, electrical and mechanical properties. Has

high strength, stiffness, high modulus, excellent dimensional stability, high tensile

and flexural strength with very good impact resistance, good creep and weathering

resistance. Has high heat distortion temperature of 190°C, so it can work at 50 °Cʙ

150 °C for a long time and with very low moisture absorption characteristics, PPE

exhibits exceptional dielectric properties even in high temperature and humidity

environments. Good chemical resistance to acids and bases but attacked by many

chlorinated and aromatic solvents

DAVE TECHNICAL SERVICES 55