Page 53 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 53

natural polymer. Cellulose itself is not a thermoplastic, since it will not melt. Yet, by

the viscose process, it is made into film (cellophane) and into fiber (rayon) that

compete with the products of its thermoplastic derivatives.

Butyrate tubes are transparent, rigid with excellent dimensional stability, high

impact strength, good chemical resistance, good clarity, sparkle and will take

decoration readily. Vacuum formed display units from CAB sheet for its deep-draw

properties, ease of formability, and impact resistance are popular.

Strengths: FDA compliant, Low water absorption, ease of fabrication, UV resistant,

good clarity, Impact resistant, Manufactured from a renewable resource (wood

pulp), resistant to most household chemicals.

Limitations: attacked by alcohol, alkalis, paint removers, and acetones

Applications: Sign panels, Packaging, tubing, Machine guards, Glazing, goggles,

Lacquers and coatings for automotive, Nail care, printing inks.

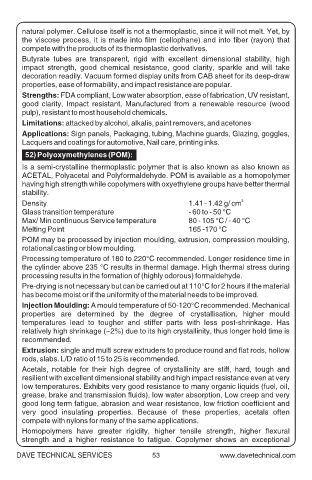

52) Polyoxymethylenes (POM):

Is a semi-crystalline thermoplastic polymer that is also known as also known as

ACETAL, Polyacetal and Polyformaldehyde. POM is available as a homopolymer

having high strength while copolymers with oxyethylene groups have better thermal

stability.

Density 1.41 - 1.42 g/ cm 3

Glass transition temperature - 60 to - 50 °C

Max/ Min continuous Service temperature 80 - 105 °C / - 40 °C

Melting Point 165 -170 °C

POM may be processed by injection moulding, extrusion, compression moulding,

rotational casting or blow moulding.

Processing temperature of 180 to 220°C recommended. Longer residence time in

the cylinder above 235 °C results in thermal damage. High thermal stress during

processing results in the formation of (highly odorous) formaldehyde.

Pre-drying is not necessary but can be carried out at 110°C for 2 hours if the material

has become moist or if the uniformity of the material needs to be improved.

Injection Moulding: A mould temperature of 50-120°C recommended. Mechanical

properties are determined by the degree of crystallisation, higher mould

temperatures lead to tougher and stiffer parts with less post-shrinkage. Has

relatively high shrinkage (~2%) due to its high crystallinity, thus longer hold time is

recommended.

Extrusion: single and multi screw extruders to produce round and flat rods, hollow

rods, slabs. L/D ratio of 15 to 25 is recommended.

Acetals, notable for their high degree of crystallinity are stiff, hard, tough and

resilient with excellent dimensional stability and high impact resistance even at very

low temperatures. Exhibits very good resistance to many organic liquids (fuel, oil,

grease, brake and transmission fluids), low water absorption, Low creep and very

good long term fatigue, abrasion and wear resistance, low friction coefficient and

very good insulating properties. Because of these properties, acetals often

compete with nylons for many of the same applications.

Homopolymers have greater rigidity, higher tensile strength, higher flexural

strength and a higher resistance to fatigue. Copolymer shows an exceptional

DAVE TECHNICAL SERVICES 53