Page 57 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 57

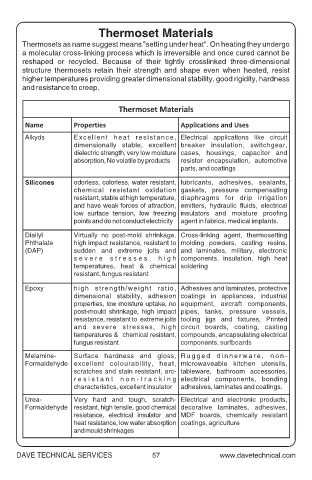

Thermoset Materials

Thermosets as name suggest means "setting under heat". On heating they undergo

a molecular cross-linking process which is irreversible and once cured cannot be

reshaped or recycled. Because of their tightly crosslinked three-dimensional

structure thermosets retain their strength and shape even when heated, resist

higher temperatures providing greater dimensional stability, good rigidity, hardness

and resistance to creep.

Thermoset Materials

Name Properties Applications and Uses

Alkyds Excellent heat resistance, Electrical applications like circuit

dimensionally stable, excellent breaker insulation, switchgear,

dielectric strength, very low moisture cases, housings, capacitor and

absorption, No volatile by products resistor encapsulation, automotive

parts, and coatings

Silicones odorless, colorless, water resistant, lubricants, adhesives, sealants,

chemical resistant oxidation gaskets, pressure compensating

resistant, stable at high temperature, diaphragms for drip irrigation

and have weak forces of attraction, emitters, hydraulic fluids, electrical

low surface tension, low freezing insulators and moisture proofing

points and do not conduct electricity agent in fabrics, medical implants.

Diallyl Virtually no post-mold shrinkage, Cross-linking agent, thermosetting

Phthalate high impact resistance, resistant to molding powders, casting resins,

(DAP) sudden and extreme jolts and and laminates, military, electronic

s e v e r e s t r e s s e s , h i g h components, insulation, high heat

temperatures, heat & chemical soldering

resistant, fungus resistant

Epoxy high strength/weight ratio, Adhesives and laminates, protective

dimensional stability, adhesion coatings in appliances, industrial

properties, low moisture uptake, no equipment, aircraft components,

post-mould shrinkage, high impact pipes, tanks, pressure vessels,

resistance, resistant to extreme jolts tooling jigs and fixtures, Printed

and severe stresses, high circuit boards, coating, casting

temperatures & chemical resistant, compounds, encapsulating electrical

fungus resistant components, surfboards

Melamine- Surface hardness and gloss, R u g g e d d i n n e r w a r e , n o n -

Formaldehyde excellent colourability, heat, microwaveable kitchen utensils,

scratches and stain resistant, arc- tableware, bathroom accessories,

r e s i s t a n t n o n - t r a c k i n g electrical components, bonding

characteristics, excellent insulator adhesives, laminates and coatings.

Urea- Very hard and tough, scratch- Electrical and electronic products,

Formaldehyde resistant, high tensile, good chemical decorative laminates, adhesives,

resistance, electrical insulator and MDF boards, chemically resistant

heat resistance, low water absorption coatings, agriculture

and mould shrinkages

DAVE TECHNICAL SERVICES 57