Page 56 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 56

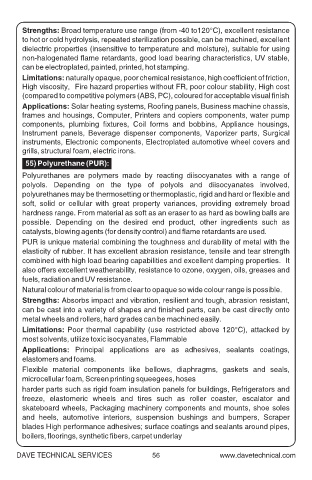

Strengths: Broad temperature use range (from -40 to120°C), excellent resistance

to hot or cold hydrolysis, repeated sterilization possible, can be machined, excellent

dielectric properties (insensitive to temperature and moisture), suitable for using

non-halogenated flame retardants, good load bearing characteristics, UV stable,

can be electroplated, painted, printed, hot stamping.

Limitations: naturally opaque, poor chemical resistance, high coefficient of friction,

High viscosity, Fire hazard properties without FR, poor colour stability, High cost

(compared to competitive polymers (ABS, PC), coloured for acceptable visual finish

Applications: Solar heating systems, Roofing panels, Business machine chassis,

frames and housings, Computer, Printers and copiers components, water pump

components, plumbing fixtures, Coil forms and bobbins, Appliance housings,

Instrument panels, Beverage dispenser components, Vaporizer parts, Surgical

instruments, Electronic components, Electroplated automotive wheel covers and

grills, structural foam, electric irons.

55) Polyurethane (PUR):

Polyurethanes are polymers made by reacting diisocyanates with a range of

polyols. Depending on the type of polyols and diisocyanates involved,

polyurethanes may be thermosetting or thermoplastic, rigid and hard or flexible and

soft, solid or cellular with great property variances, providing extremely broad

hardness range. From material as soft as an eraser to as hard as bowling balls are

possible. Depending on the desired end product, other ingredients such as

catalysts, blowing agents (for density control) and flame retardants are used.

PUR is unique material combining the toughness and durability of metal with the

elasticity of rubber. It has excellent abrasion resistance, tensile and tear strength

combined with high load bearing capabilities and excellent damping properties. It

also offers excellent weatherability, resistance to ozone, oxygen, oils, greases and

fuels, radiation and UV resistance.

Natural colour of material is from clear to opaque so wide colour range is possible.

Strengths: Absorbs impact and vibration, resilient and tough, abrasion resistant,

can be cast into a variety of shapes and finished parts, can be cast directly onto

metal wheels and rollers, hard grades can be machined easily.

Limitations: Poor thermal capability (use restricted above 120°C), attacked by

most solvents, utilize toxic isocyanates, Flammable

Applications: Principal applications are as adhesives, sealants coatings,

elastomers and foams.

Flexible material components like bellows, diaphragms, gaskets and seals,

microcellular foam, Screen printing squeegees, hoses

harder parts such as rigid foam insulation panels for buildings, Refrigerators and

freeze, elastomeric wheels and tires such as roller coaster, escalator and

skateboard wheels, Packaging machinery components and mounts, shoe soles

and heels, automotive interiors, suspension bushings and bumpers, Scraper

blades High performance adhesives; surface coatings and sealants around pipes,

boilers, floorings, synthetic fibers, carpet underlay

DAVE TECHNICAL SERVICES 56