Page 52 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 52

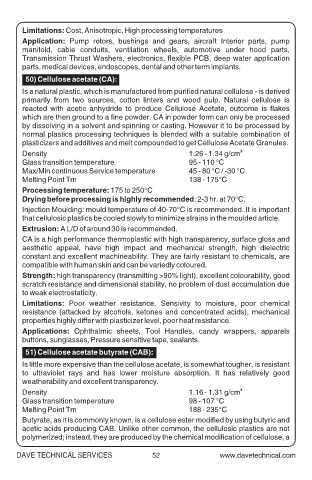

Limitations: Cost, Anisotropic, High processing temperatures

Application: Pump rotors, bushings and gears, aircraft Interior parts, pump

manifold, cable conduits, ventilation wheels, automotive under hood parts,

Transmission Thrust Washers, electronics, flexible PCB, deep water application

parts, medical devices, endoscopes, dental and other term implants.

50) Cellulose acetate (CA):

Is a natural plastic, which is manufactured from purified natural cellulose - is derived

primarily from two sources, cotton linters and wood pulp. Natural cellulose is

reacted with acetic anhydride to produce Cellulose Acetate, outcome is flakes

which are then ground to a fine powder. CA in powder form can only be processed

by dissolving in a solvent and spinning or casting. However it to be processed by

normal plastics processing techniques is blended with a suitable combination of

plasticizers and additives and melt compounded to get Cellulose Acetate Granules.

Density 1.26 - 1.34 g/cm 3

Glass transition temperature 95 - 110 °C

Max/Min continuous Service temperature 45 - 80 °C / -30 °C

Melting Point Tm 138 - 175°C

Processing temperature: 175 to 250°C

Drying before processing is highly recommended: 2-3 hr. at 70°C.

Injection Moulding: mould temperature of 40-70°C is recommended. It is important

that cellulosic plastics be cooled slowly to minimize strains in the moulded article.

Extrusion: A L/D of around 30 is recommended.

CA is a high performance thermoplastic with high transparency, surface gloss and

aesthetic appeal, have high impact and mechanical strength, high dielectric

constant and excellent machineability. They are fairly resistant to chemicals, are

compatible with human skin and can be variedly coloured.

Strength: high transparency (transmitting >90% light), excellent colourability, good

scratch resistance and dimensional stability, no problem of dust accumulation due

to weak electrostaticity.

Limitations: Poor weather resistance, Sensivity to moisture, poor chemical

resistance (attacked by alcohols, ketones and concentrated acids), mechanical

properties highly differ with plasticizer level, poor heat resistance.

Applications: Ophthalmic sheets, Tool Handles, candy wrappers, apparels

buttons, sunglasses, Pressure sensitive tape, sealants.

51) Cellulose acetate butyrate (CAB):

Is little more expensive than the cellulose acetate, is somewhat tougher, is resistant

to ultraviolet rays and has lower moisture absorption. It has relatively good

weatherability and excellent transparency.

Density 1.16 - 1.31 g/cm 3

Glass transition temperature 98 - 107 °C

Melting Point Tm 188 - 235°C

Butyrate, as it is commonly known, is a cellulose ester modified by using butyric and

acetic acids producing CAB. Unlike other common, the cellulosic plastics are not

polymerized; instead, they are produced by the chemical modification of cellulose, a

DAVE TECHNICAL SERVICES 52