Page 73 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 73

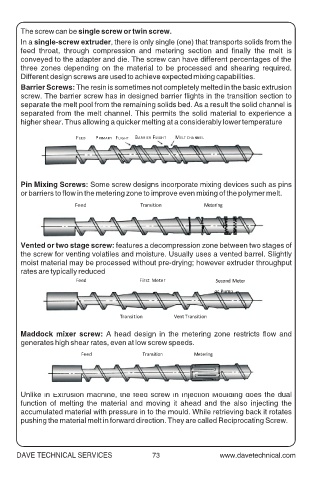

The screw can be single screw or twin screw.

In a single-screw extruder, there is only single (one) that transports solids from the

feed throat, through compression and metering section and finally the melt is

conveyed to the adapter and die. The screw can have different percentages of the

three zones depending on the material to be processed and shearing required.

Different design screws are used to achieve expected mixing capabilities.

Barrier Screws: The resin is sometimes not completely melted in the basic extrusion

screw. The barrier screw has in designed barrier flights in the transition section to

separate the melt pool from the remaining solids bed. As a result the solid channel is

separated from the melt channel. This permits the solid material to experience a

higher shear. Thus allowing a quicker melting at a considerably lower temperature

FEED PRIMARY FLIGHT BARRIER FLIGH T MELT CHA NNE L

Pin Mixing Screws: Some screw designs incorporate mixing devices such as pins

or barriers to flow in the metering zone to improve even mixing of the polymer melt.

Feed Transition Metering

Vented or two stage screw: features a decompression zone between two stages of

the screw for venting volatiles and moisture. Usually uses a vented barrel. Slightly

moist material may be processed without pre-drying; however extruder throughput

rates are typically reduced

Feed First Meter Second Meter

or Pump

Transition Vent Transition

Maddock mixer screw: A head design in the metering zone restricts flow and

generates high shear rates, even at low screw speeds.

Feed Transition Metering

Unlike in Extrusion machine, the feed screw in Injection Moulding does the dual

function of melting the material and moving it ahead and the also injecting the

accumulated material with pressure in to the mould. While retrieving back it rotates

pushing the material melt in forward direction. They are called Reciprocating Screw.

DAVE TECHNICAL SERVICES 73