Page 75 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 75

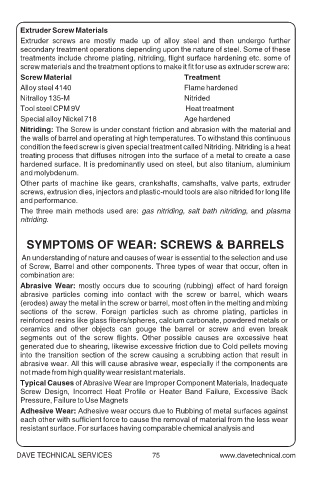

Extruder Screw Materials

Extruder screws are mostly made up of alloy steel and then undergo further

secondary treatment operations depending upon the nature of steel. Some of these

treatments include chrome plating, nitriding, flight surface hardening etc. some of

screw materials and the treatment options to make it fit for use as extruder screw are:

Screw Material Treatment

Alloy steel 4140 Flame hardened

Nitralloy 135-M Nitrided

Tool steel CPM 9V Heat treatment

Special alloy Nickel 718 Age hardened

Nitriding: The Screw is under constant friction and abrasion with the material and

the walls of barrel and operating at high temperatures. To withstand this continuous

condition the feed screw is given special treatment called Nitriding. Nitriding is a heat

treating process that diffuses nitrogen into the surface of a metal to create a case

hardened surface. It is predominantly used on steel, but also titanium, aluminium

and molybdenum.

Other parts of machine like gears, crankshafts, camshafts, valve parts, extruder

screws, extrusion dies, injectors and plastic-mould tools are also nitrided for long life

and performance.

The three main methods used are: gas nitriding, salt bath nitriding, and plasma

nitriding.

SYMPTOMS OF WEAR: SCREWS & BARRELS

An understanding of nature and causes of wear is essential to the selection and use

of Screw, Barrel and other components. Three types of wear that occur, often in

combination are:

Abrasive Wear: mostly occurs due to scouring (rubbing) effect of hard foreign

abrasive particles coming into contact with the screw or barrel, which wears

(erodes) away the metal in the screw or barrel, most often in the melting and mixing

sections of the screw. Foreign particles such as chrome plating, particles in

reinforced resins like glass fibers/spheres, calcium carbonate, powdered metals or

ceramics and other objects can gouge the barrel or screw and even break

segments out of the screw flights. Other possible causes are excessive heat

generated due to shearing, likewise excessive friction due to Cold pellets moving

into the transition section of the screw causing a scrubbing action that result in

abrasive wear. All this will cause abrasive wear, especially if the components are

not made from high quality wear resistant materials.

Typical Causes of Abrasive Wear are Improper Component Materials, Inadequate

Screw Design, Incorrect Heat Profile or Heater Band Failure, Excessive Back

Pressure, Failure to Use Magnets

Adhesive Wear: Adhesive wear occurs due to Rubbing of metal surfaces against

each other with sufficient force to cause the removal of material from the less wear

resistant surface. For surfaces having comparable chemical analysis and

DAVE TECHNICAL SERVICES 75