Page 74 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 74

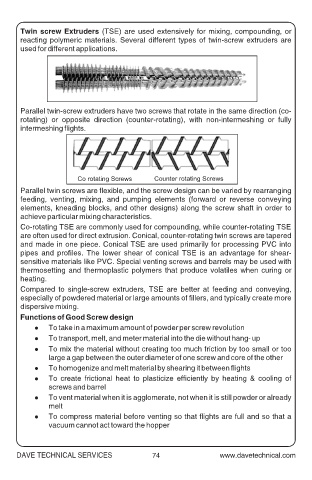

Twin screw Extruders (TSE) are used extensively for mixing, compounding, or

reacting polymeric materials. Several different types of twin-screw extruders are

used for different applications.

Parallel twin-screw extruders have two screws that rotate in the same direction (co-

rotating) or opposite direction (counter-rotating), with non-intermeshing or fully

intermeshing flights.

Co rotating Screws Counter rotating Screws

Parallel twin screws are flexible, and the screw design can be varied by rearranging

feeding, venting, mixing, and pumping elements (forward or reverse conveying

elements, kneading blocks, and other designs) along the screw shaft in order to

achieve particular mixing characteristics.

Co-rotating TSE are commonly used for compounding, while counter-rotating TSE

are often used for direct extrusion. Conical, counter-rotating twin screws are tapered

and made in one piece. Conical TSE are used primarily for processing PVC into

pipes and profiles. The lower shear of conical TSE is an advantage for shear-

sensitive materials like PVC. Special venting screws and barrels may be used with

thermosetting and thermoplastic polymers that produce volatiles when curing or

heating.

Compared to single-screw extruders, TSE are better at feeding and conveying,

especially of powdered material or large amounts of fillers, and typically create more

dispersive mixing.

Functions of Good Screw design

lTo take in a maximum amount of powder per screw revolution

-

lTo transport, melt, and meter material into the die without hang up

lTo mix the material without creating too much friction by too small or too

large a gap between the outer diameter of one screw and core of the other

lTo homogenize and melt material by shearing it between flights

lTo create frictional heat to plasticize efficiently by heating & cooling of

screws and barrel

lTo vent material when it is agglomerate, not when it is still powder or already

melt

lTo compress material before venting so that flights are full and so that a

vacuum cannot act toward the hopper

DAVE TECHNICAL SERVICES 74