Page 80 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 80

BLOW MOULDING

Blow moulding is a versatile, cost-effective manufacturing process in which air

pressure inflates heated plastic in a mould cavity producing hollow parts. It is widely

used for production of products from small bottles, tubes to large containers and

barrels.

In general, there are three main types of blow moulding: Extrusion Blow Moulding

(EBM), Injection Blow Moulding (IBM) and Injection Stretch Blow Moulding (ISBM).

Extrusion blow moulding is the most common and widely used of the three.

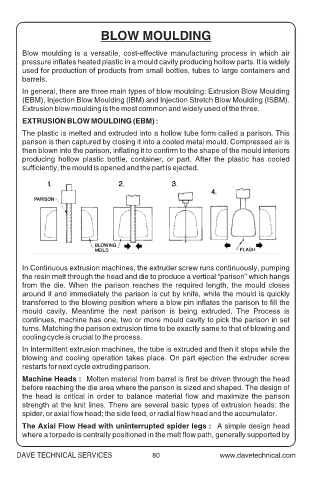

EXTRUSION BLOW MOULDING (EBM) :

The plastic is melted and extruded into a hollow tube form called a parison. This

parison is then captured by closing it into a cooled metal mould. Compressed air is

then blown into the parison, inflating it to confirm to the shape of the mould interiors

producing hollow plastic bottle, container, or part. After the plastic has cooled

sufficiently, the mould is opened and the part is ejected.

In Continuous extrusion machines, the extruder screw runs continuously, pumping

the resin melt through the head and die to produce a vertical “parison” which hangs

from the die. When the parison reaches the required length, the mould closes

around it and immediately the parison is cut by knife, while the mould is quickly

transferred to the blowing position where a blow pin inflates the parison to fill the

mould cavity. Meantime the next parison is being extruded. The Process is

continues, machine has one, two or more mould cavity to pick the parison in set

turns. Matching the parison extrusion time to be exactly same to that of blowing and

cooling cycle is crucial to the process.

In Intermittent extrusion machines, the tube is extruded and then it stops while the

blowing and cooling operation takes place. On part ejection the extruder screw

restarts for next cycle extruding parison.

Machine Heads : Molten material from barrel is first be driven through the head

before reaching the die area where the parison is sized and shaped. The design of

the head is critical in order to balance material flow and maximize the parison

strength at the knit lines. There are several basic types of extrusion heads: the

spider, or axial flow head; the side feed, or radial flow head and the accumulator.

The Axial Flow Head with uninterrupted spider legs : A simple design head

where a torpedo is centrally positioned in the melt flow path, generally supported by

DAVE TECHNICAL SERVICES 80