Page 83 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 83

3 D BLOW MOULDING TECHNOLOGY:

Conventional blow moulding processes are not ideally suited to produce long

narrow complicated, three-dimensional tubular shapes such as fuel tank filler pipes,

automotive air ducts, tubes used in household appliances, etc. They inevitably

results in welding seams at the pinch areas and potentially large amounts of flash at

the mould parting line producing excessive scrap. In some cases, flash can weigh

multiple times the weight of the moulding itself. In 3D blow moulding, a parison sized

according to the article diameter is directed by special devices directly into the

cavity of the blow mould avoiding pinch areas and welding seams on either side of

the article and minimizing overall material usage. 3D is used with intermittent

extrusion blow moulding and can be used with multiple materials (Co-Extrusion) like

rigid with elastic material and short glass fibre reinforced materials.

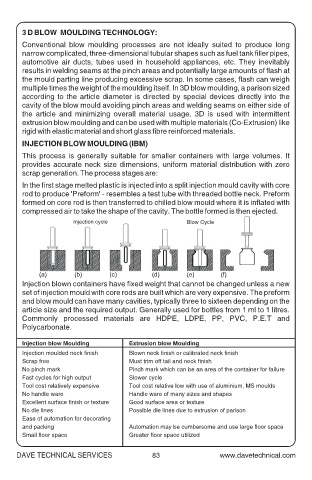

INJECTION BLOW MOULDING (IBM)

This process is generally suitable for smaller containers with large volumes. It

provides accurate neck size dimensions, uniform material distribution with zero

scrap generation. The process stages are:

In the first stage melted plastic is injected into a split injection mould cavity with core

rod to produce 'Preform' - resembles a test tube with threaded bottle neck. Preform

formed on core rod is then transferred to chilled blow mould where it is inflated with

compressed air to take the shape of the cavity. The bottle formed is then ejected.

Injection cycle Blow Cycle

(a) (b) (d) (e) (f)

Injection blown containers have fixed weight that cannot be changed unless a new

set of injection mould with core rods are built which are very expensive. The preform

and blow mould can have many cavities, typically three to sixteen depending on the

article size and the required output. Generally used for bottles from 1 ml to 1 litres.

Commonly processed materials are HDPE, LDPE, PP, PVC, P.E.T and

Polycarbonate.

Injection blow Moulding Extrusion blow Moulding

Injection moulded neck finish Blown neck finish or calibrated neck finish

Scrap free Must trim off tail and neck finish

No pinch mark Pinch mark which can be an area of the container for failure

Fast cycles for high output Slower cycle

Tool cost relatively expensive Tool cost relative low with use of aluminium, MS moulds

No handle ware Handle ware of many sizes and shapes

Excellent surface finish or texture Good surface area or texture

No die lines Possible die lines due to extrusion of parison

Ease of automation for decorating

and packing Automation may be cumbersome and use large floor space

Small floor space Greater floor space utilized

DAVE TECHNICAL SERVICES 83