Page 86 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 86

provides a clean appearance

• Sidewalls & Draft:

Textures are commonly applied to

mould surfaces enhance cosmetic

surface appearance. Draft is

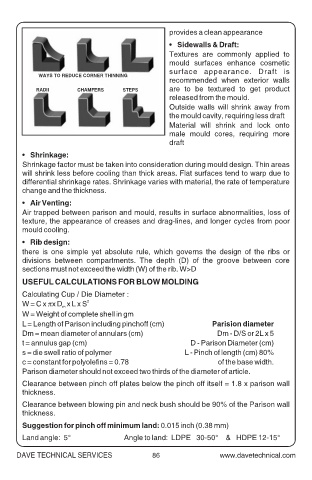

WAYS TO REDUCE CORNER THINNING

recommended when exterior walls

RADII CHAMFERS STEPS are to be textured to get product

released from the mould.

Outside walls will shrink away from

the mould cavity, requiring less draft

Material will shrink and lock onto

male mould cores, requiring more

draft

• Shrinkage:

Shrinkage factor must be taken into consideration during mould design. Thin areas

will shrink less before cooling than thick areas. Flat surfaces tend to warp due to

differential shrinkage rates. Shrinkage varies with material, the rate of temperature

change and the thickness.

• Air Venting:

Air trapped between parison and mould, results in surface abnormalities, loss of

texture, the appearance of creases and drag-lines, and longer cycles from poor

mould cooling.

• Rib design:

there is one simple yet absolute rule, which governs the design of the ribs or

divisions between compartments. The depth (D) of the groove between core

sections must not exceed the width (W) of the rib. W>D

USEFUL CALCULATIONS FOR BLOW MOLDING

Calculating Cup / Die Diameter :

W = C x px D x L x S 2

m

W = Weight of complete shell in gm

L = Length of Parison including pinchoff (cm) Parision diameter

Dm = mean diameter of annulars (cm) Dm - D/S or 2L x 5

t = annulus gap (cm) D - Parison Diameter (cm)

s = die swell ratio of polymer L - Pinch of length (cm) 80%

c = constant for polyolefins = 0.78 of the base width.

Parison diameter should not exceed two thirds of the diameter of article.

Clearance between pinch off plates below the pinch off itself = 1.8 x parison wall

thickness.

Clearance between blowing pin and neck bush should be 90% of the Parison wall

thickness.

Suggestion for pinch off minimum land: 0.015 inch (0.38 mm)

Land angle: 5° Angle to land: LDPE 30-50° & HDPE 12-15°

DAVE TECHNICAL SERVICES 86