Page 84 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 84

INJECTION STRETCH BLOW MOULDING (ISBM) :

Best known for producing PET bottles. ISBM uses the same procedures as IBM

where the preform is produced by Injection moulding and then transferred to a blow

mould, but prior to

blowing, inside the

mould the preform is

f i r s t s t r e t c h e d

mechanically with a

stretch rod.

As the rod travels down

low-pressure air is

introduced blowing a

'bubble'. Once the

stretch rod is fully

e x t e n d e d , h i g h -

pressure air blows the

expanded bubble into

the shape of the blow

mould. This biaxial stretching of material increases the tensile strength, barrier

properties, drop impact, clarity and top load in the container. This also helps in

reducing weight of bottles. ISBM is used for extremely high volume (multi-million)

runs of products such as jars, containers for packaging, kitchenware and bottles for

water, juices, carbonated beverage, liquor and feeding bottles. Equipments setup

and tooling are very expensive.

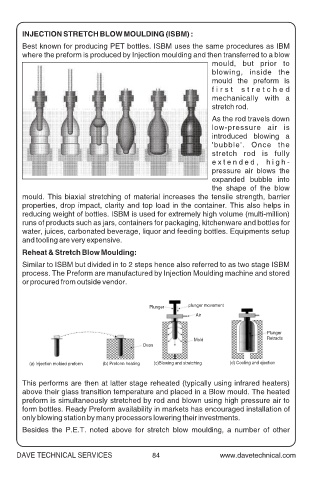

Reheat & Stretch Blow Moulding:

Similar to ISBM but divided in to 2 steps hence also referred to as two stage ISBM

process. The Preform are manufactured by Injection Moulding machine and stored

or procured from outside vendor.

Plunger plunger movement

Air

Plunger

Mold Retracts

Oven

(a) Injection molded preform (b) Preform heating (c)Blowing and stretching (d) Cooling and ejection

This performs are then at latter stage reheated (typically using infrared heaters)

above their glass transition temperature and placed in a Blow mould. The heated

preform is simultaneously stretched by rod and blown using high pressure air to

form bottles. Ready Preform availability in markets has encouraged installation of

only blowing station by many processors lowering their investments.

Besides the P.E.T. noted above for stretch blow moulding, a number of other

DAVE TECHNICAL SERVICES 84