Page 81 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 81

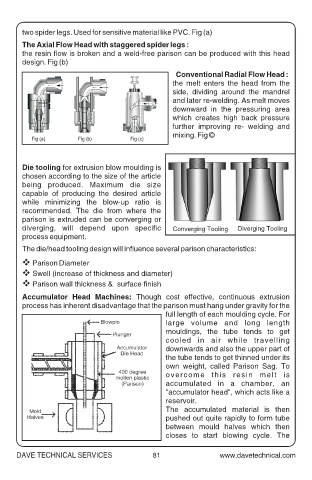

two spider legs. Used for sensitive material like PVC. Fig (a)

The Axial Flow Head with staggered spider legs :

the resin flow is broken and a weld-free parison can be produced with this head

design. Fig (b)

Conventional Radial Flow Head :

the melt enters the head from the

side, dividing around the mandrel

and later re-welding. As melt moves

downward in the pressuring area

which creates high back pressure

further improving re- welding and

mixing. Fig ©

Fig (a) Fig (b) Fig (c)

Die tooling for extrusion blow moulding is

chosen according to the size of the article

being produced. Maximum die size

capable of producing the desired article

while minimizing the blow-up ratio is

recommended. The die from where the

parison is extruded can be converging or

diverging, will depend upon specific Converging Tooling Diverging Tooling

process equipment.

The die/head tooling design will influence several parison characteristics:

vParison Diameter

vSwell (increase of thickness and diameter)

vParison wall thickness & surface finish

Accumulator Head Machines: Though cost effective, continuous extrusion

process has inherent disadvantage that the parison must hang under gravity for the

full length of each moulding cycle. For

large volume and long length

mouldings, the tube tends to get

cooled in air while travelling

downwards and also the upper part of

the tube tends to get thinned under its

own weight, called Parison Sag. To

overcome this resin melt is

accumulated in a chamber, an

"accumulator head", which acts like a

reservoir.

The accumulated material is then

pushed out quite rapidly to form tube

between mould halves which then

closes to start blowing cycle. The

DAVE TECHNICAL SERVICES 81