Page 90 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 90

INJECTION MOULDING

Injection moulding is a process of forming an article by forcing molten plastic

material under pressure into a mould where it is cooled, solidified and

subsequently released by opening the two halves of the mould.

Injection moulding produces high-quality parts with consistent wall thickness and

dimensional accuracy, often used in mass-production and prototyping. The process

is capable of producing an infinite variety of part designs containing an equally

infinite variety of details such as threads, springs and hinges, and all in a single

moulding operation.

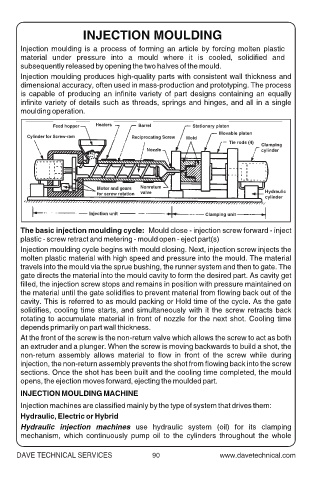

Feed hopper Heaters Barrel Stationary platen

Movable platen

Cylinder for Screw-ram Reciprocating Screw Mold

Tie rods (4)

Clamping

Nozzle cylinder

Motor and gears Nonretum

for screw rotation valve Hydraulic

cylinder

Injection unit Clamping unit

The basic injection moulding cycle: Mould close - injection screw forward - inject

plastic - screw retract and metering - mould open - eject part(s)

Injection moulding cycle begins with mould closing. Next, injection screw injects the

molten plastic material with high speed and pressure into the mould. The material

travels into the mould via the sprue bushing, the runner system and then to gate. The

gate directs the material into the mould cavity to form the desired part. As cavity get

filled, the injection screw stops and remains in position with pressure maintained on

the material until the gate solidifies to prevent material from flowing back out of the

cavity. This is referred to as mould packing or Hold time of the cycle. As the gate

solidifies, cooling time starts, and simultaneously with it the screw retracts back

rotating to accumulate material in front of nozzle for the next shot. Cooling time

depends primarily on part wall thickness.

At the front of the screw is the non-return valve which allows the screw to act as both

an extruder and a plunger. When the screw is moving backwards to build a shot, the

non-return assembly allows material to flow in front of the screw while during

injection, the non-return assembly prevents the shot from flowing back into the screw

sections. Once the shot has been built and the cooling time completed, the mould

opens, the ejection moves forward, ejecting the moulded part.

INJECTION MOULDING MACHINE

Injection machines are classified mainly by the type of system that drives them:

Hydraulic, Electric or Hybrid

Hydraulic injection machines use hydraulic system (oil) for its clamping

mechanism, which continuously pump oil to the cylinders throughout the whole

DAVE TECHNICAL SERVICES 90