Page 95 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 95

without significant loss of properties, since the skin, which can be made of virgin

material, dominates properties and appearance.

Liquid injection moulding:

Process that involves an integrated system for proportioning, mixing, and

dispensing dual-component liquid resin formulations and directly injecting the

resultant mix into a mould which is clamped under pressure.

2-Shot Injection Moulding:

This technology produces a part with two different raw materials or colors in a single

operation. The machine has two injection units: one vertical and one horizontal. By

using a rotating mould, the machine automatically produces a substrate of one resin

or colour and over moulds the part with the second resin or colour.

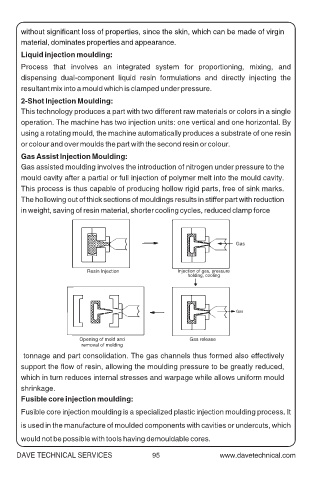

Gas Assist Injection Moulding:

Gas assisted moulding involves the introduction of nitrogen under pressure to the

mould cavity after a partial or full injection of polymer melt into the mould cavity.

This process is thus capable of producing hollow rigid parts, free of sink marks.

The hollowing out of thick sections of mouldings results in stiffer part with reduction

in weight, saving of resin material, shorter cooling cycles, reduced clamp force

Gas

Resin Injection Injection of gas, pressure

holding, cooling

Gas

Opening of mold and Gas release

removal of molding

tonnage and part consolidation. The gas channels thus formed also effectively

support the flow of resin, allowing the moulding pressure to be greatly reduced,

which in turn reduces internal stresses and warpage while allows uniform mould

shrinkage.

Fusible core injection moulding:

Fusible core injection moulding is a specialized plastic injection moulding process. It

is used in the manufacture of moulded components with cavities or undercuts, which

would not be possible with tools having demouldable cores.

DAVE TECHNICAL SERVICES 95