Page 100 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 100

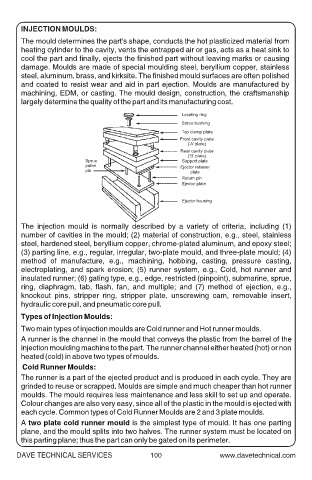

INJECTION MOULDS:

The mould determines the part's shape, conducts the hot plasticized material from

heating cylinder to the cavity, vents the entrapped air or gas, acts as a heat sink to

cool the part and finally, ejects the finished part without leaving marks or causing

damage. Moulds are made of special moulding steel, beryllium copper, stainless

steel, aluminum, brass, and kirksite. The finished mould surfaces are often polished

and coated to resist wear and aid in part ejection. Moulds are manufactured by

machining, EDM, or casting. The mould design, construction, the craftsmanship

largely determine the quality of the part and its manufacturing cost.

Locating ring

Sprue bushing

Top clamp plate

Front cavity plate

(‘A’ plate)

Rear cavity plate

(‘B’ plate)

Sprue Support plate

puller Ejector retainer

pin plate

Return pin

Ejector plate

Ejector housing

The injection mould is normally described by a variety of criteria, including (1)

number of cavities in the mould; (2) material of construction, e.g., steel, stainless

steel, hardened steel, beryllium copper, chrome-plated aluminum, and epoxy steel;

(3) parting line, e.g., regular, irregular, two-plate mould, and three-plate mould; (4)

method of manufacture, e.g., machining, hobbing, casting, pressure casting,

electroplating, and spark erosion; (5) runner system, e.g., Cold, hot runner and

insulated runner; (6) gating type, e.g., edge, restricted (pinpoint), submarine, sprue,

ring, diaphragm, tab, flash, fan, and multiple; and (7) method of ejection, e.g.,

knockout pins, stripper ring, stripper plate, unscrewing cam, removable insert,

hydraulic core pull, and pneumatic core pull.

Types of Injection Moulds:

Two main types of injection moulds are Cold runner and Hot runner moulds.

A runner is the channel in the mould that conveys the plastic from the barrel of the

injection moulding machine to the part. The runner channel either heated (hot) or non

heated (cold) in above two types of moulds.

Cold Runner Moulds:

The runner is a part of the ejected product and is produced in each cycle. They are

grinded to reuse or scrapped. Moulds are simple and much cheaper than hot runner

moulds. The mould requires less maintenance and less skill to set up and operate.

Colour changes are also very easy, since all of the plastic in the mould is ejected with

each cycle. Common types of Cold Runner Moulds are 2 and 3 plate moulds.

A two plate cold runner mould is the simplest type of mould. It has one parting

plane, and the mould splits into two halves. The runner system must be located on

this parting plane; thus the part can only be gated on its perimeter.

DAVE TECHNICAL SERVICES 100