Page 105 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 105

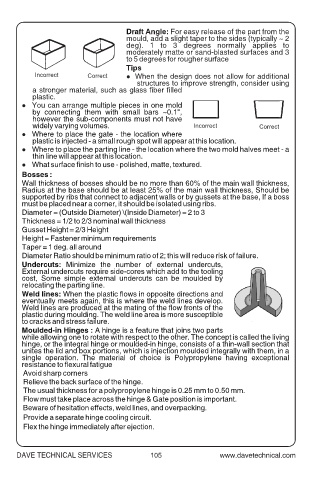

Draft Angle: For easy release of the part from the

mould, add a slight taper to the sides (typically ~ 2

deg). 1 to 3 degrees normally applies to

moderately matte or sand-blasted surfaces and 3

to 5 degrees for rougher surface

Tips

Incorrect Correct lWhen the design does not allow for additional

structures to improve strength, consider using

a stronger material, such as glass fiber filled

plastic.

lYou can arrang e multiple pieces in one mold

by connecting them with small bars ~0.1",

however the sub-components must not have

widely varying volumes. Incorrect Correct

Where to place the gate - the location where

l

plastic is injected - a small rough spot will appear at this location.

Where to place the parting line - the location where the two mold halves meet - a

l

thin line will appear at this location.

What surface finish to use - polished, matte, textured.

l

Bosses :

Wall thickness of bosses should be no more than 60% of the main wall thickness,

Radius at the base should be at least 25% of the main wall thickness, Should be

supported by ribs that connect to adjacent walls or by gussets at the base, If a boss

must be placed near a corner, it should be isolated using ribs.

Diameter = (Outside Diameter) \(Inside Diameter) = 2 to 3

Thickness = 1/2 to 2/3 nominal wall thickness

Gusset Height = 2/3 Height

Height = Fastener minimum requirements

Taper = 1 deg. all around

Diameter Ratio should be minimum ratio of 2; this will reduce risk of failure.

Undercuts: Minimize the number of external undercuts,

External undercuts require side-cores which add to the tooling

cost, Some simple external undercuts can be moulded by

relocating the parting line.

Weld lines: When the plastic flows in opposite directions and

eventually meets again, this is where the weld lines develop.

Weld lines are produced at the mating of the flow fronts of the

plastic during moulding. The weld line area is more susceptible

to cracks and stress failure.

Moulded-in Hinges : A hinge is a feature that joins two parts

while allowing one to rotate with respect to the other. The concept is called the living

hinge, or the integral hinge or moulded-in hinge, consists of a thin-wall section that

unites the lid and box portions, which is injection moulded integrally with them, in a

single operation. The material of choice is Polypropylene having exceptional

resistance to flexural fatigue

Avoid sharp corners

Relieve the back surface of the hinge.

The usual thickness for a polypropylene hinge is 0.25 mm to 0.50 mm.

Flow must take place across the hinge & Gate position is important.

Beware of hesitation effects, weld lines, and overpacking.

Provide a separate hinge cooling circuit.

Flex the hinge immediately after ejection.

DAVE TECHNICAL SERVICES 105