Page 102 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 102

Cleaner moulding process Wear caused by filled materials

Eliminates nozzle freeze Thermal damage to sensitive materials

Consistent heat within the cavity Stringent temp. control required

Materials of Mould Construction:

Choosing the proper mould material depends on the application. For prototyping

where few test pieces run is required, a pre-hardened steel or aluminum is used to

minimize cost and allow easy modification of the tool during the prototype stage. For

large production runs use of good quality too steel is important.

R

For very large moulds pre hardened steel P-20 or NAK -55 is used.

Smaller moulds for high production requires hardened punch (cores) and cavities.

S-7 is used long production runs moulds & H-13 is used where withstanding very

high tempering temperatures and high mould processing temperatures without loss

of hardness is requried It is also used to produce hot runner manifolds.

In cases where high wear and abrasion-resistance are required, or in cases where

the environment produces a lot of condensation, stainless steel 420 will be the

mould steel of choice. A2, ASP23 or D-2 steels may be used as cavity inserts in

areas of high wear.

All tool steels can be protected with some kind of plating to protect against wear,

abrasion and corrosion. Only stainless steel can be repaired through welding and

machining. On steels which have been plated, repairs can only take place after the

plating has been removed. After repair, it will then have to be reapplied.

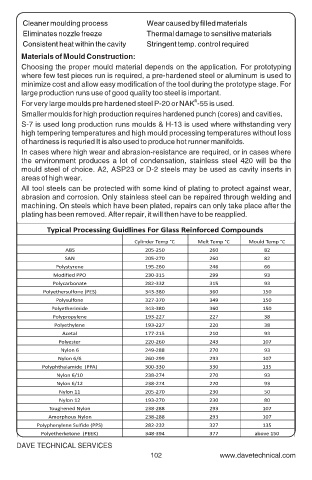

Typical Processing Guidlines For Glass Reinforced Compounds

Cylinder Temp °C Melt Temp °C Mould Temp °C

ABS 205-250 260 82

SAN 205-270 260 82

Polystyrene 195-260 246 66

Modified PPO 230-315 299 93

Polycarbonate 282-332 315 93

Polyethersulfone (PES) 343-380 360 150

Polysulfone 327-370 349 150

Polyetherimide 343-380 360 150

Polypropylene 193-227 227 38

Polyethylene 193-227 220 38

Acetal 177-215 210 93

Polyester 220-260 243 107

Nylon 6 249-288 270 93

Nylon 6/6 260-299 293 107

Polyphthalamide (PPA) 300-330 330 135

Nylon 6/10 238-274 270 93

Nylon 6/12 238-274 270 93

Nylon 11 205-270 230 50

Nylon 12 193-270 230 80

Toughened Nylon 238-288 293 107

Amorphous Nylon 238-288 293 107

Polyphenylene Sulfide (PPS) 282-232 327 135

Polyetherketone (PEEK) 348-394 377 above 150

DAVE TECHNICAL SERVICES

102