Page 101 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 101

A three plate mould has two parting planes and the mould splits into three sections,

providing flexibility in gating location and be placed anywhere along part surface.

Insert Mould : an over-mould to mould plastic around other materials, such as

metals or even other plastic inserts, such as sleeves for drill housings, screw drivers,

handles, electrical plugs, others

2-Shot Moulds (also 3-Shot and 4-Shot Moulds) : a cost-effective way to produce

parts with 2 or more colors moulded at the same time; eliminates a secondary

process to add logos, graphics or text

Stack Moulds : high production moulds for multiple parting lines; can produce

multiple parts more economically over a large production run

Unscrewing Moulds- to produce parts with internal or external threads, such as

nuts, nut augers, sprinkler heads

Other types of Injection moulds are Stripper Ejector Mould, Split Cavity Mould

and Slide mould.

The runner is situated in the mould and is heated to keep temperature above the

melting point of the plastic. This provide for very less or No scrap, so No wastage or

regrind. Hot runners moulds are popular in high multi cavities moulds. A major

disadvantage of a hot runner is that it is much more expensive, requires costly

maintenance and more skill to operate.

Hot Runner Moulds: Injection moulds in which the runners are kept hot and

insulated from the chilled cavities. Plastic freeze off occurs at gate of cavity while

runners are in a separate plate and are not ejected with the piece. A hot runner

system is divided into two parts: the manifold and the drops. The manifold has

channels that convey the plastic on a single plane, parallel to the parting line, to a

point above the cavity. The drops, situated perpendicular to the manifold, convey the

plastic from the manifold to the part. They are very popular in high production moulds

with lot of cavities.

Types of Hot Runner Moulds: In the externally heated type, molten plastic runs

within a solid manifold and within the nozzles. In the internally heated, (now

obsolete) the plastic flows directly over slender heaters inside oversized runners.

Externally heated hot runner channels have the lowest pressure drop of any runner

system, are better for colour changes and provide consistent plastic melt in the

runner system. There are no places for material to hang up and degrade, so are good

for thermally sensitive materials. Hot runners mould are expensive but provide

savings by reducing plastic waste and cycle time.

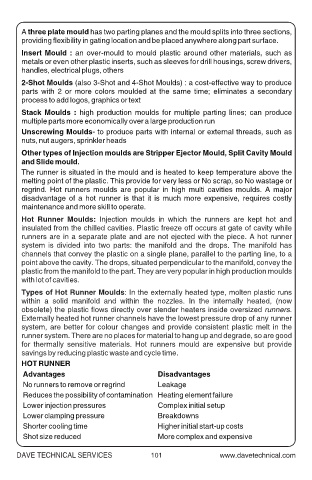

HOT RUNNER

Advantages Disadvantages

No runners to remove or regrind Leakage

Reduces the possibility of contamination Heating element failure

Lower injection pressures Complex initial setup

Lower clamping pressure Breakdowns

Shorter cooling time Higher initial start-up costs

Shot size reduced More complex and expensive

DAVE TECHNICAL SERVICES 101