Page 104 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 104

Parts should be tested in the worst case environment.

MOULDING PRODUCT DESIGN TIPS &

GENERAL GUIDELINES

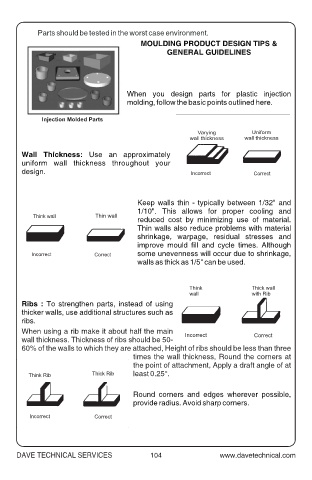

When you design parts for plastic injection

molding, follow the basic points outlined here.

Injection Molded Parts

Varying Uniform

wall thickness wall thickness

Wall Thickness: Use an approximately

uniform wall thickness throughout your

design. Incorrect Correct

Keep walls thin - typically between 1/32" and

1/10". This allows for proper cooling and

Think wall Thin wall

reduced cost by minimizing use of material.

Thin walls also reduce problems with material

shrinkage, warpage, residual stresses and

improve mould fill and cycle times. Although

Incorrect Correct some unevenness will occur due to shrinkage,

walls as thick as 1/5" can be used.

Think Thick wall

wall with Rib

Ribs : To strengthen parts, instead of using

thicker walls, use additional structures such as

ribs.

When using a rib make it about half the main

Incorrect Correct

wall thickness. Thickness of ribs should be 50-

60% of the walls to which they are attached, Height of ribs should be less than three

times the wall thickness, Round the corners at

the point of attachment, Apply a draft angle of at

Think Rib Thick Rib least 0.25°.

Round corners and edges wherever possible,

provide radius. Avoid sharp corners.

Incorrect Correct

DAVE TECHNICAL SERVICES 104