Page 109 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 109

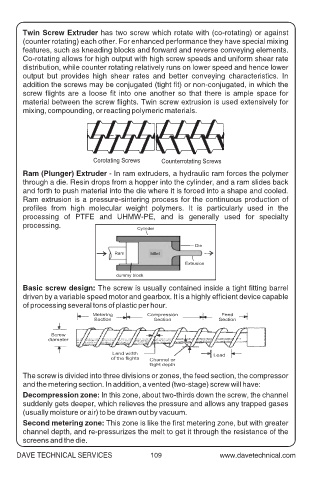

Twin Screw Extruder has two screw which rotate with (co-rotating) or against

(counter rotating) each other. For enhanced performance they have special mixing

features, such as kneading blocks and forward and reverse conveying elements.

Co-rotating allows for high output with high screw speeds and uniform shear rate

distribution, while counter rotating relatively runs on lower speed and hence lower

output but provides high shear rates and better conveying characteristics. In

addition the screws may be conjugated (tight fit) or non-conjugated, in which the

screw flights are a loose fit into one another so that there is ample space for

material between the screw flights. Twin screw extrusion is used extensively for

mixing, compounding, or reacting polymeric materials.

Corotating Screws Counterrotating Screws

Ram (Plunger) Extruder - In ram extruders, a hydraulic ram forces the polymer

through a die. Resin drops from a hopper into the cylinder, and a ram slides back

and forth to push material into the die where it is forced into a shape and cooled.

Ram extrusion is a pressure-sintering process for the continuous production of

profiles from high molecular weight polymers. It is particularly used in the

processing of PTFE and UHMW-PE, and is generally used for specialty

processing.

Cylinder

Die

Ram billet

Extrusion

dummy block

Basic screw design: The screw is usually contained inside a tight fitting barrel

driven by a variable speed motor and gearbox. It is a highly efficient device capable

of processing several tons of plastic per hour.

The screw is divided into three divisions or zones, the feed section, the compressor

and the metering section. In addition, a vented (two-stage) screw will have:

Decompression zone: In this zone, about two-thirds down the screw, the channel

suddenly gets deeper, which relieves the pressure and allows any trapped gases

(usually moisture or air) to be drawn out by vacuum.

Second metering zone: This zone is like the first metering zone, but with greater

channel depth, and re-pressurizes the melt to get it through the resistance of the

screens and the die.

DAVE TECHNICAL SERVICES 109