Page 112 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 112

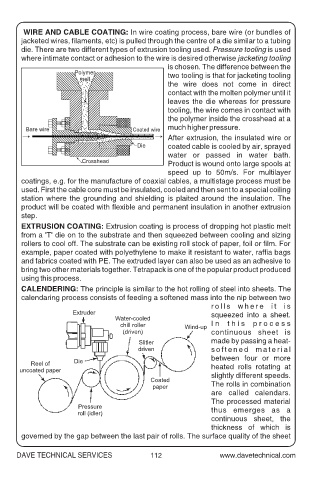

WIRE AND CABLE COATING: In wire coating process, bare wire (or bundles of

jacketed wires, filaments, etc) is pulled through the centre of a die similar to a tubing

die. There are two different types of extrusion tooling used. Pressure tooling is used

where intimate contact or adhesion to the wire is desired otherwise jacketing tooling

is chosen. The difference between the

Polymer

melt two tooling is that for jacketing tooling

the wire does not come in direct

contact with the molten polymer until it

leaves the die whereas for pressure

tooling, the wire comes in contact with

the polymer inside the crosshead at a

Bare wire Coated wire much higher pressure.

After extrusion, the insulated wire or

Die coated cable is cooled by air, sprayed

water or passed in water bath.

Crosshead

Product is wound onto large spools at

speed up to 50m/s. For multilayer

coatings, e.g. for the manufacture of coaxial cables, a multistage process must be

used. First the cable core must be insulated, cooled and then sent to a special coiling

station where the grounding and shielding is plaited around the insulation. The

product will be coated with flexible and permanent insulation in another extrusion

step.

EXTRUSION COATING: Extrusion coating is process of dropping hot plastic melt

from a 'T' die on to the substrate and then squeezed between cooling and sizing

rollers to cool off. The substrate can be existing roll stock of paper, foil or film. For

example, paper coated with polyethylene to make it resistant to water, raffia bags

and fabrics coated with PE. The extruded layer can also be used as an adhesive to

bring two other materials together. Tetrapack is one of the popular product produced

using this process.

CALENDERING: The principle is similar to the hot rolling of steel into sheets. The

calendaring process consists of feeding a softened mass into the nip between two

r o l l s w h e r e i t i s

Extruder squeezed into a sheet.

Water-cooled

chill roller Wind-up I n t h i s p r o c e s s

(driven) continuous sheet is

Slitler made by passing a heat-

driven s o f t e n e d m a t e r i a l

between four or more

Die

Reel of

uncoated paper heated rolls rotating at

slightly different speeds.

Coated

paper The rolls in combination

are called calendars.

The processed material

Pressure

roll (idler) thus emerges as a

continuous sheet, the

thickness of which is

governed by the gap between the last pair of rolls. The surface quality of the sheet

DAVE TECHNICAL SERVICES 112