Page 115 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 115

characteristic property to the final film, such as

stiffness, heat-sealability, impermeability or

1

resistance to some environment, all of which

properties would be impossible to attain with any

2 single material. This technology is used on any of the

3

processes as blown film, overjacketing, tubing and

sheets extrusions.

CAST FILM EXTRUSION: The cast film process

differs from the blown film process through the fast

quench and virtual unidirectional orientation capabilities. These characteristics allow

a cast film line to operate at higher production rates while producing amazing optics.

Polymer melt is extruded through a flat die. Immediately after exiting the die, the

molten curtain is passed onto rotating water cooled chill roll or into water quench tank

to “freeze” the film. The speed of the roller controls the draw ratio and final film

thickness which then is passed downstream where the edges are trimmed, corona

treatment is applied (if a fabrication process such as printing or coating is required)

and the film is wound into rolls. Cast film is usually made in a thickness range of 20 to

200 microns, and is used in applications with good optical properties such as gloss,

transparency, surface smoothness, good tear resistance with toughness and

flexibility.

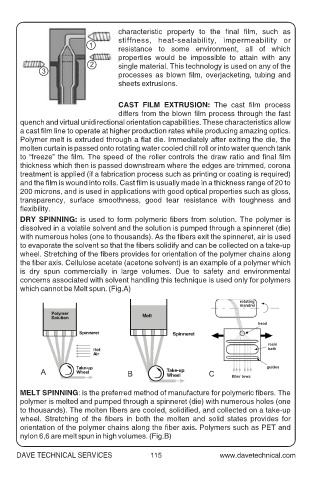

DRY SPINNING: is used to form polymeric fibers from solution. The polymer is

dissolved in a volatile solvent and the solution is pumped through a spinneret (die)

with numerous holes (one to thousands). As the fibers exit the spinneret, air is used

to evaporate the solvent so that the fibers solidify and can be collected on a take-up

wheel. Stretching of the fibers provides for orientation of the polymer chains along

the fiber axis. Cellulose acetate (acetone solvent) is an example of a polymer which

is dry spun commercially in large volumes. Due to safety and environmental

concerns associated with solvent handling this technique is used only for polymers

which cannot be Melt spun. (Fig.A)

rotating

mandrel

head

resin

bath

guides

A B C fiber tows

MELT SPINNING: is the preferred method of manufacture for polymeric fibers. The

polymer is melted and pumped through a spinneret (die) with numerous holes (one

to thousands). The molten fibers are cooled, solidified, and collected on a take-up

wheel. Stretching of the fibers in both the molten and solid states provides for

orientation of the polymer chains along the fiber axis. Polymers such as PET and

nylon 6,6 are melt spun in high volumes. (Fig.B)

DAVE TECHNICAL SERVICES 115