Page 120 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 120

Die imbalance: An unbalanced die can result in the extrudate leaving the die at

varying speeds leading to deformation.

Co extrusion: The main challenge in the co extrusion process is to ensure a perfect

interface between the two materials.

Die Deformation: Die deformation takes place due to high internal pressure: this is

true while extruding wide and thin films.

All die surfaces must be free from defects otherwise unwanted patterns will appear

on the extruded product. Also overheating the melt is to be avoided at all costs, or the

product will not form properly on solidification. Once solid, the product material can

be wound, spun, or cut in defined lengths depending upon its intended end-use

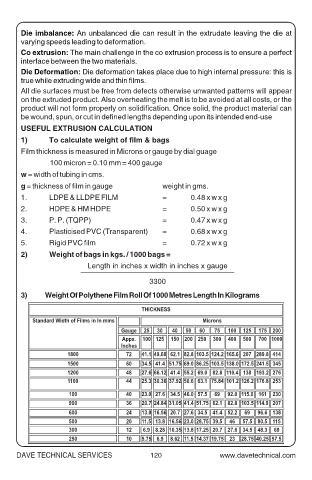

USEFUL EXTRUSION CALCULATION

1) To calculate weight of film & bags

Film thickness is measured in Microns or gauge by dial guage

100 micron = 0.10 mm = 400 gauge

w = width of tubing in cms.

g = thickness of film in gauge weight in gms.

1. LDPE & LLDPE FILM = 0.48 x w x g

2. HDPE & HM HDPE = 0.50 x w x g

3. P. P. (TQPP) = 0.47 x w x g

4. Plasticised PVC (Transparent) = 0.68 x w x g

5. Rigid PVC film = 0.72 x w x g

2) Weight of bags in kgs. / 1000 bags =

Length in inches x width in inches x gauge

3300

3) Weight Of Polythene Film Roll Of 1000 Metres Length In Kilograms

THICKNESS

Standard Width of Films in In mms Microns

Gauge 25 30 40 50 60 75 100 125 175 200

Appx. 100 125 150 200 250 300 400 500 700 1000

Inches

1800 72 41.1 49.68 62.1 82.8 103.5 124.2 165.6 207 289.8 414

1500 60 34.5 41.4 51.75 69.0 86.25 103.5 138.0 172.5 241.5 345

1200 48 27.6 66.12 41.4 55.2 69.0 82.8 110.4 138 193.2 276

1100 44 25.3 30.36 37.92 50.6 63.1 75.84 101.2 126.2 176.8 253

100 40 23.0 27.6 34.5 46.0 57.5 69 92.0 115.0 161 230

900 36 20.7 24.84 31.05 41.4 51.75 62.1 82.8 103.5 114.9 207

600 24 13.8 16.56 20.7 27.6 34.5 41.4 52.2 69 96.6 138

500 20 11.5 13.8 16.56 23.0 28.75 39.5 46 57.5 80.5 115

300 12 6.9 8.28 10.35 13.8 17.25 20.7 27.6 34.5 48.3 69

250 10 5.75 6.9 8.62 11.5 14.37 19.75 23 28.75 40.25 57.5

DAVE TECHNICAL SERVICES 120