Page 119 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 119

A

4

3

1 2

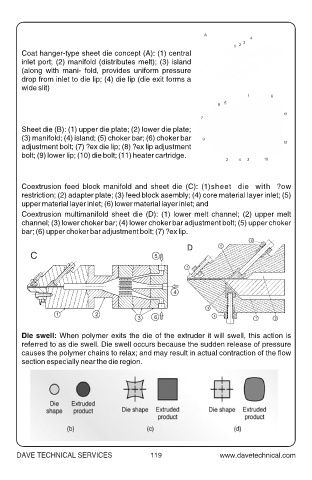

Coat hanger-type sheet die concept (A): (1) central

inlet port; (2) manifold (distributes melt); (3) island

(along with mani- fold, provides uniform pressure

drop from inlet to die lip; (4) die lip (die exit forms a

wide slit)

1 6

5

8

11

7

Sheet die (B): (1) upper die plate; (2) lower die plate;

(3) manifold; (4) island; (5) choker bar; (6) choker bar 9

11

adjustment bolt; (7) ?ex die lip; (8) ?ex lip adjustment

bolt; (9) lower lip; (10) die bolt; (11) heater cartridge.

2 4 3 10

Coextrusion feed block manifold and sheet die (C): (1) sheet die with ?ow

restriction; (2) adapter plate; (3) feed block asembly; (4) core material layer inlet; (5)

upper material layer inlet; (6) lower material layer inlet; and

Coextrusion multimanifold sheet die (D): (1) lower melt channel; (2) upper melt

channel; (3) lower choker bar; (4) lower choker bar adjustment bolt; (5) upper choker

bar; (6) upper choker bar adjustment bolt; (7) ?ex lip.

6

D 5

C 5

7

4

3

1 2

3 6 4 1 2

Die swell: When polymer exits the die of the extruder it will swell, this action is

referred to as die swell. Die swell occurs because the sudden release of pressure

causes the polymer chains to relax; and may result in actual contraction of the flow

section especially near the die region.

DAVE TECHNICAL SERVICES 119