Page 118 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 118

sheet thicknesses with one die.

Extrusion dies may be categorized by the type of product being produced.

There are five types of extrusion dies: (1) profile (moulding and rod), (2) tubing, (3)

wire coating, (4) film and (5) sheet dies.

Profiles: Shapes are varied, and typically are holes for filament, annular rings for

pipe and tube, or geometric patterned shapes for items such as vinyl siding and

window frame stock.

Tubing: an in-line spiral manifold extrusion die assembly for making small diameter

hose and tubing, with adjustable wall centering.

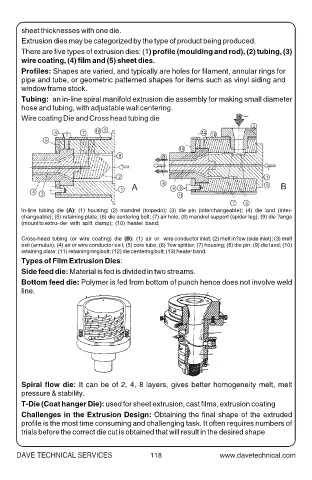

Wire coating Die and Cross head tubing die

2

10 9

6 7 12 13

5

10

8 3

2 1

A 4 8 5 B

1 9

4 3 11

7 6

In-line tubing die (A): (1) housing; (2) mandrel (torpedo); (3) die pin (interchangeable); (4) die land (inter-

changeable); (5) retaining plate; (6) die centering bolt; (7) air hole; (8) mandrel support (spider leg); (9) die ?ange

(mount to extru- der with split clamp); (10) heater band;

Cross-head tubing (or wire coating) die (B): (1) air or wire conductor inlet; (2) melt in?ow (side inlet); (3) melt

exit (annulus); (4) air or wire conductor exit; (5) core tube; (6) ?ow splitter; (7) housing; (8) die pin; (9) die land; (10)

retaining plate; (11) retaining ring bolt; (12) die centering bolt; (13) heater band.

Types of Film Extrusion Dies:

Side feed die: Material is fed is divided in two streams.

Bottom feed die: Polymer is fed from bottom of punch hence does not involve weld

line.

Spiral flow die: It can be of 2, 4, 8 layers, gives better homogeneity melt, melt

pressure & stability.

T-Die (Coat hanger Die): used for sheet extrusion, cast films, extrusion coating

Challenges in the Extrusion Design: Obtaining the final shape of the extruded

profile is the most time consuming and challenging task. It often requires numbers of

trials before the correct die cut is obtained that will result in the desired shape

DAVE TECHNICAL SERVICES 118