Page 113 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 113

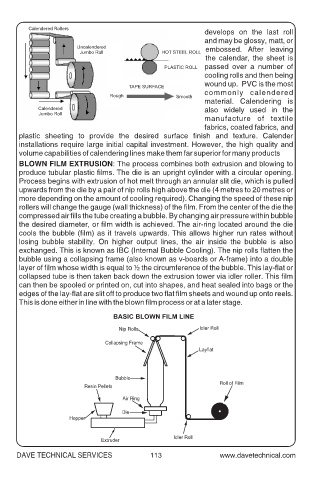

Calendered Rollers

develops on the last roll

and may be glossy, matt, or

Uncalendered

Jumbo Roll HOT STEEL ROLL embossed. After leaving

the calendar, the sheet is

PLASTIC ROLL passed over a number of

cooling rolls and then being

wound up. PVC is the most

TAPE SURFACE

commonly calendered

Rough Smooth

material. Calendering is

Calendered also widely used in the

Jumbo Roll

manufacture of textile

fabrics, coated fabrics, and

plastic sheeting to provide the desired surface finish and texture. Calender

installations require large initial capital investment. However, the high quality and

volume capabilities of calendering lines make them far superior for many products

BLOWN FILM EXTRUSION: The process combines both extrusion and blowing to

produce tubular plastic films. The die is an upright cylinder with a circular opening.

Process begins with extrusion of hot melt through an annular slit die, which is pulled

upwards from the die by a pair of nip rolls high above the die (4 metres to 20 metres or

more depending on the amount of cooling required). Changing the speed of these nip

rollers will change the gauge (wall thickness) of the film. From the center of the die the

compressed air fills the tube creating a bubble. By changing air pressure within bubble

the desired diameter, or film width is achieved. The air-ring located around the die

cools the bubble (film) as it travels upwards. This allows higher run rates without

losing bubble stability. On higher output lines, the air inside the bubble is also

exchanged. This is known as IBC (Internal Bubble Cooling). The nip rolls flatten the

bubble using a collapsing frame (also known as v-boards or A-frame) into a double

layer of film whose width is equal to ½ the circumference of the bubble. This lay-flat or

collapsed tube is then taken back down the extrusion tower via idler roller. This film

can then be spooled or printed on, cut into shapes, and heat sealed into bags or the

edges of the lay-flat are slit off to produce two flat film sheets and wound up onto reels.

This is done either in line with the blown film process or at a later stage.

BASIC BLOWN FILM LINE

Nip Rolls Idler Roll

Collapsing Frame

Layflat

Bubble

Roll of Film

Resin Pellets

Air Ring

Die

Hopper

Idler Roll

Extruder

DAVE TECHNICAL SERVICES 113