Page 107 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 107

EXTRUSION MOULDING

Extrusion refers to a continuous process in which hot plastic melt is forced out

through a die or series of die that forms a profile which is sized, cooled and solidified

to required final dimensions. The word Extrusion comes from latin word extrudere

meaning 'to thrust out. It produces continuous, straight profiles having a constant

cross section which are cut to length. Production rates are measured in linear units,

such as feet/minute, ordinarily are reasonably high.

The die determines the final shape of product extruded which can be solid round,

square, hollow tubes, T, C or L shapes, etc. producing sheet, pipe, film, tubing and

profiles. Consider squeezing a toothpaste tube, its opening act as die and the paste

comes out in solid rod form. The change in the opening shape will change the shape

(cross section) of tube coming out.

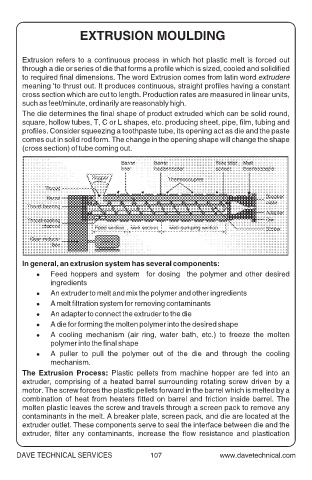

In general, an extrusion system has several components:

lFeed hoppers and system for dosing the polymer and other desired

ingredients

lAn extruder to melt and mix the polymer and other ingredients

lA melt filtration system for removing contaminants

lAn adapter to connect the extruder to the die

lA die for forming the molten polymer into the desired shape

lA cooling mechanism (air ring, water bath, etc.) to freeze the molten

polymer into the final shape

lA puller to pull the polymer out of the die and through the cooling

mechanism.

The Extrusion Process: Plastic pellets from machine hopper are fed into an

extruder, comprising of a heated barrel surrounding rotating screw driven by a

motor. The screw forces the plastic pellets forward in the barrel which is melted by a

combination of heat from heaters fitted on barrel and friction inside barrel. The

molten plastic leaves the screw and travels through a screen pack to remove any

contaminants in the melt. A breaker plate, screen pack, and die are located at the

extruder outlet. These components serve to seal the interface between die and the

extruder, filter any contaminants, increase the flow resistance and plastication

DAVE TECHNICAL SERVICES 107