Page 91 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 91

moulding cycle and are commonly used by majority of moulding companies.

Electric injection machines are driven by motors. Unlike the hydraulic machines,

an electric machine only makes use of energy during closing and opening of the

clamping unit. It uses toggle system for its clamping mechanism in order to build up

tonnage. It is also faster, quieter, and has higher accuracy, but is more expensive.

Hybrid injection moulding machines take advantage of the best features of both

hydraulic and electric systems.

The injection machine has 2 main parts, an Injection unit and a Clamping unit.

Injection Unit:

The name of the injection moulding machine is generally based on the type of

injection unit Ram (plunger) type or Screw type. Further classification based on

Injection unit being vertical or horizontal.

The Ram type injection moulding machine uses a hydraulically operated plunger to

push the plastic. The high viscosity hot melt is spread into a thin layer by a "torpedo"

to allow for better contact with the heated surfaces. The melt converges at a nozzle

and is injected into the mould.

The Screw type injection moulding machine utilises motorized screw that mixes the

molten pellets and forces them to end of the cylinder. Screw does dual function of

melting (compresses, melt and convey) and pushing the material and hence called

reciprocating screw.

Injection Unit includes a hopper, a heated injection barrel encasing the screw (or

plunger), a hydraulic motor, and an injection cylinder. The system's function is to

heat the thermoplastic to the proper viscosity and inject it into the mould.

Clamping unit:

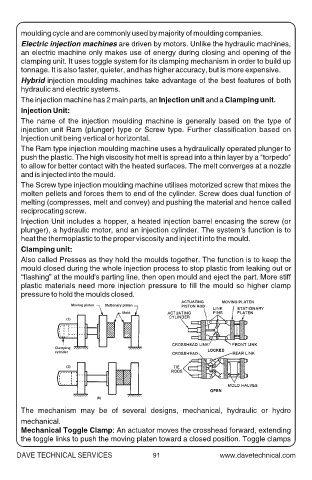

Also called Presses as they hold the moulds together. The function is to keep the

mould closed during the whole injection process to stop plastic from leaking out or

“flashing” at the mould's parting line, then open mould and eject the part. More stiff

plastic materials need more injection pressure to fill the mould so higher clamp

pressure to hold the moulds closed.

ACTUATING MOVING PLATEN

Moving platen Stationary platen PISTON ROD

Mold

(1)

Clamping

cylinder

(2)

(b)

The mechanism may be of several designs, mechanical, hydraulic or hydro

mechanical.

Mechanical Toggle Clamp: An actuator moves the crosshead forward, extending

the toggle links to push the moving platen toward a closed position. Toggle clamps

DAVE TECHNICAL SERVICES 91