Page 4 - Parker - Inks, paints and coatings industry

P. 4

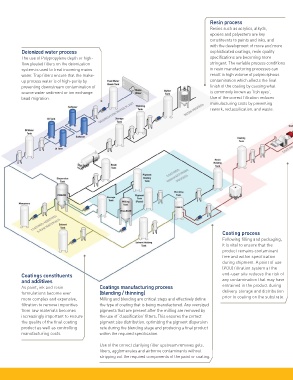

Resin process

Resins such as acrylics, alkyds,

epoxies and polyesters are key

constituents to paints and inks, and

with the development of more and more

Deionized water process sophisticated coatings, resin quality

The use of Polypropylene depth or high- specifi cations are becoming more

fl ow pleated fi lters on the deionization stringent. The variable process conditions

system is used to treat incoming mains in resin manufacturing processes can

water. Trap fi lters ensure that the make- result in high volume of polymorphous

up process water is of high-purity by contamination which affects the fi nal

preventing downstream contamination of fi nish of the coating by causing what

source water sediment or ion exchange is commonly known as ‘fi sh eyes’,

bead migration. Use of the correct fi ltration reduces

manufacturing costs by preventing

rework, reclassifi cation, and waste.

Coating process

Following fi lling and packaging,

it is vital to ensure that the

product remains contaminant

free and within specifi cation

during shipment. A point of use

(POU) fi ltration system at the

Coatings constituents end-user site reduces the risk of

and additives any contamination that may have

As paint, ink and resin Coatings manufacturing process entrained in the product during

formulations become ever (blending / thinning) delivery, storage and distribution

prior to coating on the substrate.

more complex and expensive, Milling and blending are critical steps and effectively defi ne

fi ltration to remove impurities the type of coating that is being manufactured. Any oversized

from raw materials becomes pigments that are present after the milling are removed by

increasingly important to ensure the use of ‘classifi cation’ fi lters. This ensures the correct

the quality of the fi nal coating pigment size distribution, optimizing the pigment dispersion

product as well as controlling rate during the blending stage and producing a fi nal product

manufacturing costs. within the required specifi cation.

Use of the correct clarifying fi lter upstream removes gels,

fi bers, agglomerates and airborne contaminants without

stripping out the required components of the paint or coating.