Page 4 - Parker - Instrumentation process analyzer condensed catalog

P. 4

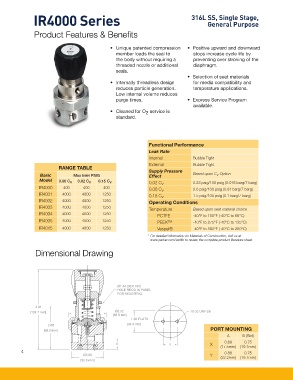

IR4000 Series 316L SS, Single Stage,

General Purpose

Product Features & Benefits

• Unique patented compression • Positive upward and downward

member loads the seal to stops increase cycle life by

the body without requiring a preventing over stroking of the

threaded nozzle or additional diaphragm.

seals.

• Selection of seat materials

• Internally threadless design for media compatibility and

reduces particle generation. temperature applications.

Low internal volume reduces

purge times. • Express Service Program

available.

• Cleaned for O service is

2

standard.

Functional Performance

Leak Rate

Internal Bubble Tight

External Bubble Tight

RANGE TABLE

Supply Pressure

v

Basic Max Inlet PSIG Effect Based upon C Option

Model 0.06 C v 0.02 C v 0.15 C v 0.02 C v 0.23 psig/100 psig (0.016 barg/7 barg)

IR4000 400 400 400 0.06 C v 0.6 psig/100 psig (0.04 barg/7 barg)

IR4001 4000 4000 1250 0.15 C v 1.5 psig/100 psig (0.1 barg/7 barg)

IR4002 4000 4000 1250 Operating Conditions

IR4003 4000 4000 1250 Temperature Based upon seat material choice

IR4004 4000 4000 1250 PCTFE -40°F to 150°F (-40°C to 66°C)

IR4005 4000 4000 1250 PEEK™ -40°F to 275°F (-40°C to 135°C)

IR4015 4000 4000 1250 Vespel® -40°F to 500°F (-40°C to 260°C)

* For detailed information on Materials of Construction, visit us at

www.parker.com/veriflo to review the complete product literature sheet.

Dimensional Drawing

PORT MOUNTING

A B (Std)

X 0.69 0.75

(17.5mm) (19.1mm)

4 0.88 0.75

Y

(22.2mm) (19.1mm)