Page 21 - Parker - L90LS Mobile directional control valve

P. 21

Catalogue HY17-8504/UK Mobile Directional Control Valve

Spool Section L90LS

The L90LS is stackable and can be supplied in combinations of B A B A

1-12 spool sections. Each section can be equipped individually

with a variety of optional functions, as well as different types of

spool and spool-actuator. This enables optimum customization to

the application and particular machine function in question.

T T

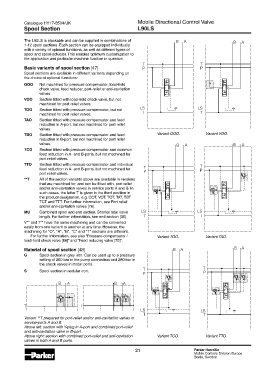

Basic variants of spool section [47] P P

Spool sections are available in different variants depending on

the choice of optional functions:

OOO Not machined for pressure compensator, load-hold

check valve, feed reducer, port-relief or anti-cavitation

valves.

VOO Section fitted with load-hold check valve, but not

machined for port relief valves.

TOO Section fitted with pressure compensator, but not LS T LS

machined for port relief valves. T

TAO Section fitted with pressure compensator and feed

reduction in A-port, but not machined for port relief

valves.

TBO Section fitted with pressure compensator and feed Variant OOO. Variant VOO.

reduction in B-port, but not machined for port relief

valves. B A B A

TCO Section fitted with pressure compensator and common

feed reduction in A- and B-ports, but not machined for

port relief valves.

TTO Section fitted with pressure compensator and individual T

feed reduction in A- and B-ports, but not machined for T P

P

port relief valves.

**T All of the section variants above are available in versions

that are machined for, and can be fitted with, port relief

and/or anti-cavitation valves in service ports A and B. In

such cases, the letter T is given in the third position in

the product designation, e.g. OOT, VOT, TOT, TAT, TBT

TCT and TTT. For further information, see Port relief

and/or anti-cavitation valves [76].

MU Combined spool and end section. Shorter total valve LS LS

length. For further information, see end section [30]. T T

V** and T** have the same machining and can be converted

easily from one variant to another at any time. However, the

machining for *O*, *A*, *B*, *C* and *T* sections are different.

For further information, see also “Pressure compensator / Variant TOO. Variant TAO.

load-hold check valve [66]” and “Feed reducing valve [75]”.

Material of spool section [48] B A B A

G Spool section in grey iron. Can be used up to a pressure

setting of 260 bar in the pump connection and 280 bar in

the shock valves in motor ports.

T

S Spool section in nodular iron. T P

P

B A B A

T T

LS LS

T T

Variant **T prepared for port-relief and/or anti-cavitation valves in

service-ports A and B.

Above left: section with Y-plug in A-port and combined port-relief

and anti-cavitation valve in B-port.

Above right: section with combined port-relief and anti-cavitation Variant TCO. Variant TTO.

valves in both A and B ports.

21 Parker Hannifin

Mobile Controls Division Europe

Borås, Sweden