Page 392 - Schmalz - Vacuum Components

P. 392

5_Kap_Greifsysteme_2016_EN_Vakuum-Greifsysteme_2016 25.02.16 17:49 Seite 392

PA01019111_inh_EN.pdf

Vacuum Area Gripping Systems SBX

Product Specifications

PA01019111_inh_EN.pdf PA01019111_inh_EN.pdf

Schmalz - The Company

Vacuum Knowledge

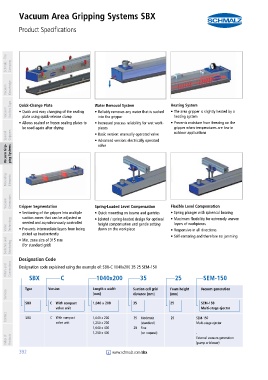

Vacuum Suction Cups Quick-Change Plate Water Removal System Heating System

• Quick and easy changing of the sealing

• The area gripper is slightly heated by a

• Reliably removes any water that is sucked

heating system

plate using quick-release clamp

into the gripper

• Allows soaked or frozen sealing plates to • Increased process reliability for wet work- • Prevents moisture from freezing on the

be used again after drying pieces gripper when temperatures are low in

Special Grippers • Basic version: manually operated valve outdoor applications

• Advanced version: electrically operated

Vacuum Grip- ping Systems valve

Mounting Elements

Vacuum Generators Gripper Segmentation Spring-Loaded Level Compensation Flexible Level Compensation

• Sectioning of the gripper into multiple • Quick mounting on beams and gantries • Spring plunger with spherical bearing

suction zones that can be adjusted as

• Jointed / spring-loaded design for optimal

• Maximum flexibility for extremely uneven

needed and asynchronously controlled

layers of workpieces

Valve Technology • Prevents intermediate layers from being height compensation and gentle setting • Responsive in all directions

down on the workpiece

picked up inadvertently • Self-centering and therefore no jamming

Switches and Monitoring • Min. zone size of 315 mm

(for standard grid)

Designation Code

Filters and Connections Designation code explained using the example of: SBX-C 1040x200 35 25 SEM-150

SBX C 1040x200 35 25 SEM-150

Type Version Length x width Suction cell grid Foam height Vacuum generation

Services [mm] distance [mm] [mm]

SBX C With compact 1,040 x 200 35 25 SEM-150

valve unit Multi-stage ejector

Contact SBX C With compact 1,040 x 200 35 Moderate 25 SEM-150

valve unit

1,250 x 200

1,040 x 400 28 (standard) Multi-stage ejector

Fine

1,250 x 400 (on request) -

Index of Products External vacuum generation

(pump or blower)

392 www.schmalz.com/sbx

PA01019111_inh_EN.pdf