Page 12 - Parker - Inks, Paints and coating filtrations

P. 12

High dirt holding capacity and life No recontamination or alteration of end product lter integrity Environmentally friendly and reduces disposable costs Retention of deformable particles over longer lter life at cost-effective process Reduces product waste and improves yield High dirt retention on single-pass ensures total protection Assured filter performance, integrity Reduces product wastage and improves yie

Advantages Consistent filter performance and fi differential pressure drop rise providing good fi and product quality Maintains coating application quality at low cost

Excellent pore size distribution Very low extractables No media migration Easy to dispose Provides rigid matrix and compatibility at high temperature and solvents Will not cause ‘fish-eyes’ or cratering on painted surface Absolute rated filter Beta 5000 (99.99%) No by-pass of coating or cratering on painted surface Consistent particle capture High flow rates and extended life and integrity

ts sh-eyes’ ciency lter effi

Benefi Will not cause ‘fi Maintains fi

Graded density matrix No surfactants, binders or adhesives ber diameter thermally bonded No requirement of core /cage Made of Phenolic resin Silicone-free materials of construction True graded density matrix Thermally welded end caps *Silicone-free option available Controlled pore size distribution ltration surface area ber shedding media

Features Uniform fi High fi Non-fi

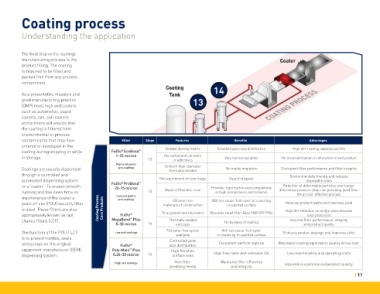

Stage 13 13 14 14

o ® EcoBond ™ o ® ProBond ™ o ® o ®

Understanding the application

Filter 1-25 micron High end paints and coatings 25-75 micron Low end paints and coatings Fulfl MegaBond ™ Plus 5-30 micron Low end coatings Fulfl Poly-Mate ™ Plus 0.25-30 micron High end coatings

Coating process

Fulfl Fulfl Core Products Coating Process

The final step in the coatings manufacturing process is the product filling. The coating lled and is required to be fi packed free from any process contaminant. As a preventative measure and good manufacturing practice (GMP) most high end coaters such as automotive, paper coaters, can, coil coaters and printers will ensure that ltered from the coating is fi environmental or process contaminants that may have entered or developed in the