Page 11 - Parker - Inks, Paints and coating filtrations

P. 11

Environmentally friendly and Selective retention of deformable particles over a longer differential pressure drop rise and so provides lter life Reduces product waste and improves yield Environmentally friendly Retention of deformable particles over a longer differential pressure drop rise lter life at cost-effective process Reduces product wastage and improves yield | 10

Advantages reduces disposal costs good fi and reduces disposable costs and so provides good fi

ts bers sh-eyes’ sh-eyes’

Benefi Easy to dispose Enables a strong rigid density matrix that does not shed fi Will not cause ‘fi or cratering on painted surface Easy to dispose Provides rigid matrix and compatibility at high temperature and solvents Will not cause ‘fi or cratering on painted surface

No requirement of core /cage Fibers made of Bi-componant polymer Silicone-free materials of No requirement of Made of Phenolic resin Silicone-free materials of

Features construction core / cage construction

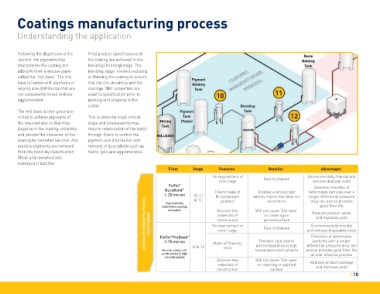

Coatings manufacturing process

Stage 10, 11 & 12 10 & 12

Filter o ® Fulfl DuraBond ™ 1-25 micron High end inks, automotive coatings and paints o ® ProBond ™ Fulfl 2-75 micron Varnish, stains, all- grade paints & high viscosity pastes

cations of Core Products Coatings Manufacturing Process

Understanding the application

Final product specifi the coating are achieved in the blending (thinning) stage. The blending stage involves reducing or thinning the coating to ensure that the tint, durability and the coatings ‘film’ properties are exact to specification prior to packing and shipping to the coater. This is often the most critical stage and consequently may require recirculation of the batch through filters to control the pigment size distribution and re

Following the dispersion of the ‘premix’ the pigments that characterize the coating are added to form a viscose paste called the ‘mill base’. The mill base is loaded with pigments of varying size distribution that are not consistently mixed and are agglomerated. The mill base is then ground or milled to achieve pigments of the required size so that they disperse in the coating uniformly and provide the character of the coating for intended fun