Page 10 - Parker - Inks, Paints and coating filtrations

P. 10

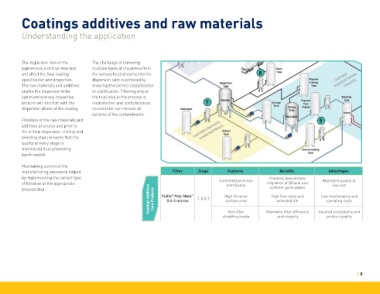

Advantages Maintains quality at low cost Low maintenance and operating costs Assured consistency and product quality | 9

Prevents downstream migration of DI tank and softener particulates High flow rates and extended life and integrity

ts ciency lter effi

Benefi Maintains fi

Coatings additives and raw materials

Controlled pore size ltration ber

Features distribution High fi surface area Non-fi shedding media

Stage 7, 8 & 9

o ® Poly-Mate ™

Filter 0.5-3 micron

Fulfl Core Products Coatings Additives

cation

The challenge of removing multiple types of impurities from the various feed streams into the dispersion tank is achieved by ensuring the correct classifi or clarification. Filtering only at the final step in the process is unproductive and costly because no one filter can remove all variants of the contaminants.

Understanding the application

The dispersion rate of the pigments is a critical step and nal coating will affect the fi specification and properties. The raw materials and additives enable the dispersion to be optimized and any impurities present will interfere with the dispersion phase of the coating. Filtration of the raw materials and additives at source and prior to the critical dispersion, milling and blending steps ensures that the quality at every stage is ma