Page 8 - Parker - Inks, Paints and coating filtrations

P. 8

Advantages High durability and life Low batch rejects and re-work No wastage / reject or re- work of coated substrate Maintains quality at low cost No recontamination or alteration of end product Assured quality of end product | 7

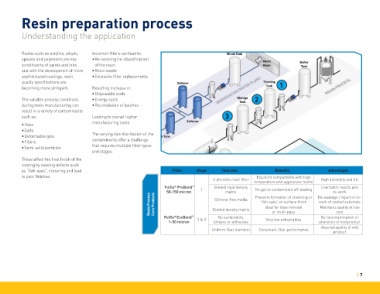

Excellent compatibility with high temperature and aggressive resins No gel or contaminant off-loading Prevents formation of cratering or Ideal for haze removal or multi-pass Very low extractables

ts nish lter performance

Benefi ‘fish-eyes’ on surface fi Consistent fi

lter

Features A phenolic resin fi Graded rigid density matrix Silicone-free media Graded density matrix No surfactants, binders or adhesives Uniform fiber diameter

Stage 1 2 & 3

o ® ProBond ™ o ® EcoBond ™

Resin preparation process

Filter 50-150 micron 1-50 micron

Fulfl Core Products Resin Process Fulfl

lter types

Incorrect filters can lead to: cation) • Re-working (re-classifi of the resin • Resin waste lter replacements • Excessive fi Resulting increase in: • Disposable costs • Energy costs • Recirculation of batches Leading to overall higher manufacturing costs. The varying size distribution of the contaminants offer a challenge that requires multiple fi and stages.

Understanding the application

Resins such as acrylics, alkyds, epoxies and polyesters are key constituents of paints and inks and with the development of more sophisticated coatings, resin cations are quality specifi becoming more stringent. The variable process conditions during resin manufacturing can result in a variety of contaminants such as: • Haze • Salts • Deformable gels • Fibers • Semi-solid particles nal finish of the These affect the fi coating by causin