Page 6 - Parker - Inks, Paints and coating filtrations

P. 6

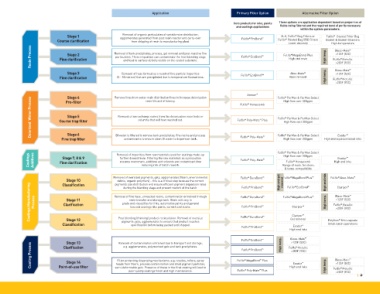

These options are application dependent based on properties of fl uids being fi ltered and the required level of purity necessary Fulfl o ® Coaxial Filter Bag Basket & Basket Strainers High-temperature Glass-Mate ™ >125F (52C) Fulfl o ® Metallic High temp. >200F (93C) Glass-Mate ™ >125F (52C) Fulfl o ® Metallic >200F (93C) High temp. Evadur ™ High end aqueous based inks Evadur ™ High end inks Fulfl o ® Abso-Mate ™ Claripor ™ High end inks Gl

Alternative Filter Option within the system parameters. XLH, Fulfl o ® Bag Filters or Fulfl o ® Pleated Bag (PB) Filters Lower viscosity Fulfl o ® MegaBond Plus High end resin Abso-Mate ® Haze removal Fulfl o ® ParMax & ParMax Select High fl ow over 300gpm Fulfl o ® ParMax & ParMax Select High fl ow over 300gpm Fulfl o ® ParMax & ParMax Select High fl ow over 300gpm Fulfl o ® ParMax & ParMax Select High fl ow over 300gpm Fulfl o ® Honeycomb Range of mats.

Primary Filter Option Core products for inks, paints and coatings applications Fulfl o ® ProBond ™ Fulfl o ® EcoBond ™ Fulfl o ® EcoBond™ Avasan ™ Fulfl o ® Honeycomb Fulfl o ® Poly-Mate ™ Plus Fulfl o ® Poly-Mate ™ Fulfl o ® Poly-Mate ™ Fulfl o ® DuraBond ™ removal Fulfl o ® ProBond ™ High end gel Fulfl o ® DuraBond ™ Fulfl o ® ProBond ™ Fulfl o ® DuraBond ™ Fulfl o ® ProBond ™ Fulfl o ® EcoBond ™ Fulfl o ® ProBond ™ High temp. Fulfl o ®

Removal of organic particulates of variable size distribution, Remove fi nes from water main distribution lines to increase deionization DI water is fi ltered to remove tank precipitates, fi ne resins and process Removal of impurities from raw materials used for coatings make-up debris, organic polymers) - this is a critical step because the correct Post blending (thinning) product recirculation. Removal of oversize Removal of contamination entrained due t

Application agglomerates generated from post resin reactor and carry-over from shipping of resin to manufacturing plant. Removal of tank precipitates, process, gel removal and post-reactive fi ne particulates. These impurities can contaminate the fi nal blending stage and lead to surface defects visible on the coated substrate. Removal of haze formed as a result of fi ne particle impurities (5 - 50 micron) that are precipitated due to temperature fl uctuations. resin life

cation cation cation lter lter cation cation cation lter

Stage 1 Course clarifi Stage 2 Fine clarifi Resin Process Stage 3 Fine clarifi Stage 4 lter Pre-fi Stage 5 Course trap fi Stage 6 Deionized Water Process Fine trap fi Stage 7, 8 & 9 Fine clarifi Coatings Additives Stage 10 Classifi Stage 11 cation Clarifi Process Stage 12 Coatings Manufacturing Classifi Stage 13 cation Clarifi Stage 14 Point-of-use fi Coating Process